Interested in seeing our new whistle for yourself? We are headed down to the 2023 Railroad Hobby Show (https://www.railroadhobbyshow.com/) in Springfield, Massachusetts this upcoming weekend, January 28 & 29, 2023, and our whistle is too! Stop by for a chance to see it up close and talk about the #470 restoration.

What's Happening in January and February?

As many of you may be familiar with, Maine winters are known for being:

Unpredictable

Bitterly cold

Full of snow and ice!

On average, our volunteers travel 1 to 3 hours one way in order to come work on the 470 restoration project. Winter travel is too dangerous and unpredictable for us to be able to ask our volunteers to make this drive. Safety first!

Plus, not sure if y’all have noticed, but while our lovely tent is really good at keeping out the snow and rain it is not heated. In fact, it is almost always a good 10 degrees colder in the tent than it is outside! We like being able to feel our fingers and toes!

So what does that mean you can expect from NESCo until we get into warmer months? We are continuing to work on cataloging historical MEC drawings. So far, over 2,000 drawings have been logged and there and many hundreds left. In addition, we all have little winter projects to do! You will also see us at two upcoming train shows:

Amherst Railway Society’s Railroad Hobby show (https://www.railroadhobbyshow.com/) from January 28 & 29, 2023

2023 Maine3Railers Train & Dollhouse Show (https://maine3railers.org/event/maine3railers-train-dollhouse-show/) on February 18, 2023 @ 10:00 am – 3:00 pm

Members will be getting a Winter newsletter in their inboxes soon!

Thanks for your understanding!

12/21/2022 Work Session

Happy holidays from the NESCo crew! Volunteers braved the cold to set out donuts and hot coffee for the Big Guy, next to a stocking hung with care on the best mantle in town!

Black's Heat Pumps showed up to the tent and brought the equipment to be installed. Ron and Al began installing the mount in the office container where the inside unit is to go. Black's will return Monday to complete the job. Paul H got more MEC drawings recorded and organized in the office. We now have about 2000 drawings accounted for.

In other areas, Bob did more assembly of the cab — drilling and bolting up both sides of the new upper front cab wall to the new side walls of the cab. Bolts will be soon be replaced with hot rivets. Bob, Paul V and Leverett came up with a plan for a platform for the dome area on the boiler, and installed the hand winch cable that will be used for the throttle valve removal.

Attendees were Ron and Al Jenkins, Bob, Paul V, Paul H, and Leverett.

12/4/2022 Work Session

Bob, Matt, Paul and Leverett worked on making a mount on the steam dome for the davit crane, so the throttle valve can easily be removed. Bob brought his profile cutter and along with his plasma cutter was able to cut a piece of 1/2” plate to fit over the dome studs along with some spacer washers. This part fit perfectly and made the job of making the base mount much easier that it would have been otherwise. Two braces were added to the crane base and were secured to the trailer side rails using 2 old 2 inch boiler tubes.

Ron and Al laid out and drilled the holes in the back of the tender cistern for the hold down brackets and are now in place with temporary fitup bolts until we are ready to rivet them in place. Roger and Will made gaskets from tar paper that will be placed between the hold down brackets and tender cistern. Afterwards, Leverett showed Will how to oil 470's machinery.

Present for the December 4th workday were Bob D., Paul V., Ron and Al Jenkins, Roger Bennati, Matt Hofer, Leverett Fernald and new volunteer Will Ternay.

11/26/2022 Work Session

Progress, progress, progress! This weekend, work continued on the cab restoration. Bill Alexander stopped by the shop to discuss the details of the cab windows with Bob. A fine woodworker, Bill is making all new windows for the cab. He and Bob have been collaborating on design and fit, as Bob leads the metal work on the cab. Bob then resumed work on the cab, Paul and Hanna helping as needed. The front panel has been completely cut down to size and now awaits drilling and riveting.

The mag drill is currently tied up on the tender, however, as Ron and Al resumed hole drilling for rivets. There are many holes drilled, but many more to go!

Paul, Kerri and Leverett erected staging in anticipation of accessing the steam dome. Once all the tubes and flues are removed, we will then need access to the steam dome for the next portion of the boiler survey preparation.

In addition, we all worked to finish winterizing the tent. Hanna and Leverett cleaned up the blocking and air tank brackets that were outside, and Hanna took all of the paint home to store it for the winter. Ron, Al and Hanna finished rearranging bay 2 in building 1 so one of the DESR hirail trucks could be stored.

Kerri also got to cook on the new grill purchased last year, and we all enjoyed a hot lunch to warm us up! Kerri took many photos and updated her Facebook page — Maine Central Steam Locomotive #470 Restoration Project— with an excellent set of “Before and After” photos. Check it out here! All in all, a good day.

Present were Bob D., Bill A., Ron and Al J., Kerri, Paul V., Hanna and Leverett.

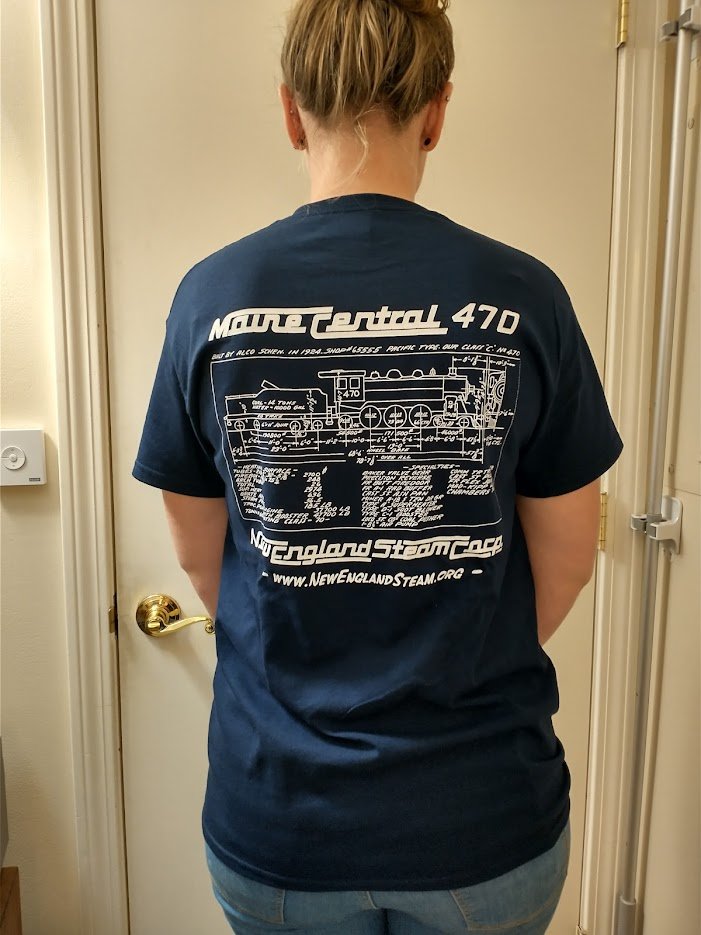

New Merch Alert!

Two new items are here just in time for your holiday shopping! Check out our new 2023 calendars and t-shirt design in the store today.

2023 calendars are currently available for pre-order and will begin shipping the first week of December. Reserve yours on the store today. Supplies are limited to 50!

Our new “Blueprint” t-shirt is available in sizes medium through 5X-Large. Get yours today!

In addition, we will be selling both at the Eastern Maine Annual Train show this Saturday, November 19th from 10am to 3pm.

11/13/2022 Work Session

The work session everyone has been anticipating is finally here! Today we picked up the new tender cistern and successfully placed it on the rebuilt tender trucks and frame.

Thanks to all the effort over the last year to prepare for this lift (e.g., 23 July work session, 30 July work session), the crew was able to complete the lift on the first attempt and achieve perfect alignment. This view of the action is taken from the cab of Downeast Scenic Railroad 54, which was used to move the tender throughout the lift to position the frame into position. Once the crane and other equipment was positioned, the lift only took ~13 minutes.

Look at how much room is in the shop with the tender out. We seriously don’t know what to do with all the spare room. This space will be critical when we start riveting the tender in the spring. There are about 2,500 hot rivets to set!

Thanks to all the NESCo volunteers and members who made this a reality!

Present for the lift were: Paul VS, Paul H, Robert, Leverett, Bob, Kieth, Al, Ron, Hanna. and Jim

11/5/2022 Work Session

This week, work continued on several major projects:

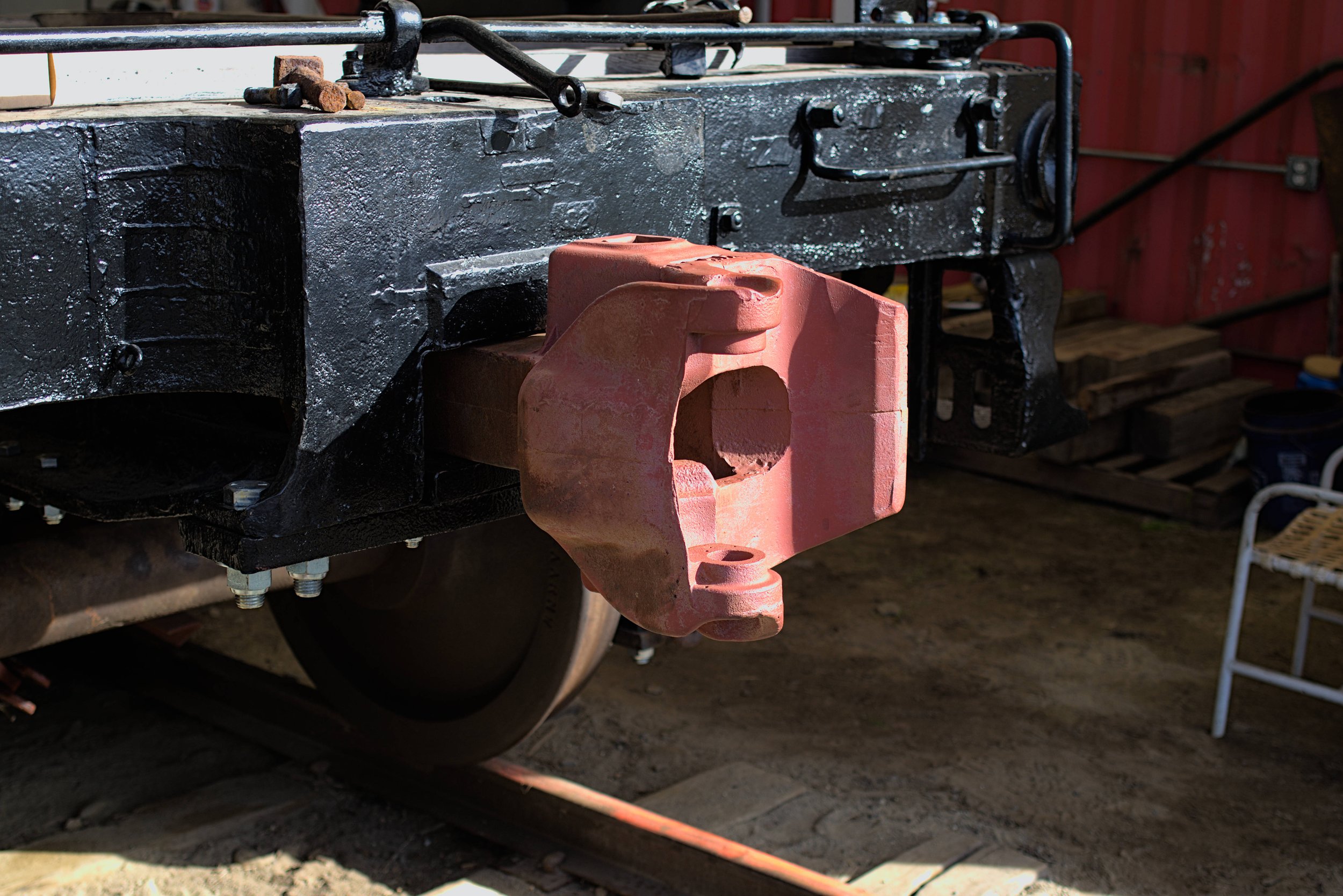

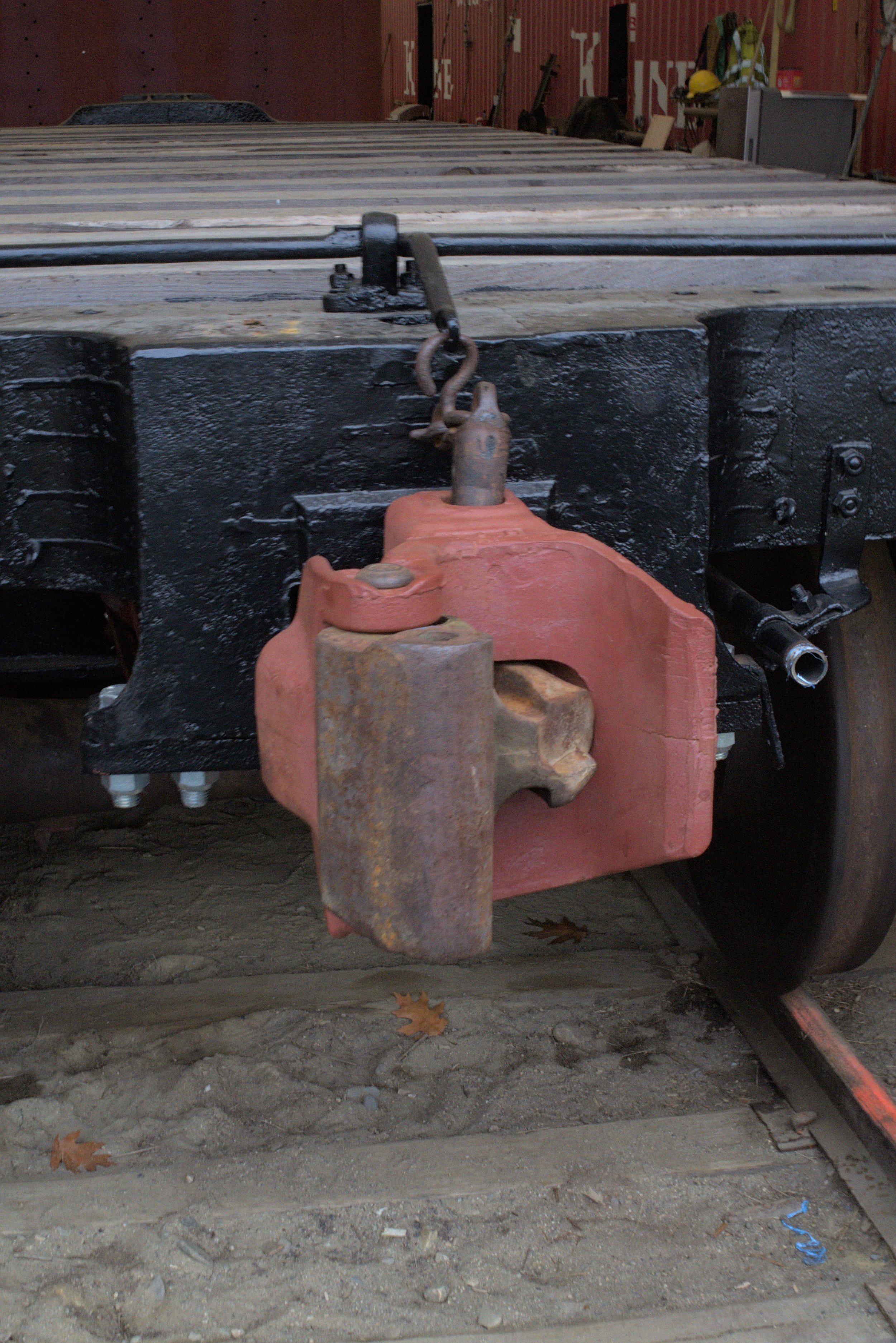

The coupler was installed on the tender frame! Yes, we got the knuckle on as well. We had to borrow Downeast Scenic Railroad 1055 to double-check we got all the pieces in correctly, it is a bit of a jig saw puzzle.

The new front sheet of the cab continues to receive adjustments for a perfect fit. One remaining decision to be made is the configuration of the front-facing windows. Over the course of 470's service, their size and placement varied.

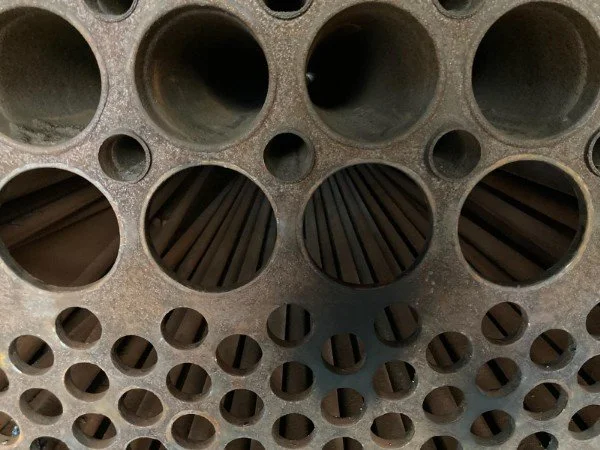

With winter weather coming, it is time to turn back to some of the smaller jobs sitting around the shop -- including the rebuild of 470's Detroit Model A lubricator. The lubricator reservoir was left full of oil and the steam lines full of water when weatherized in 1954. Volunteers have spent the last few winters carefully stripping off the thick coats of black paint and cleaning all the oil from the block. Now, attention is being turned to inspecting and cleaning the steam circuits. At least one coil is split and will need to be addressed before reassembly.

Additionally, work continued to weatherize the tent.

Present: Robert, Al, Ron, Leverett, Hanna, Paul VS, Bob

10/30/2022 Report from Bob DeWachter's Home Shop

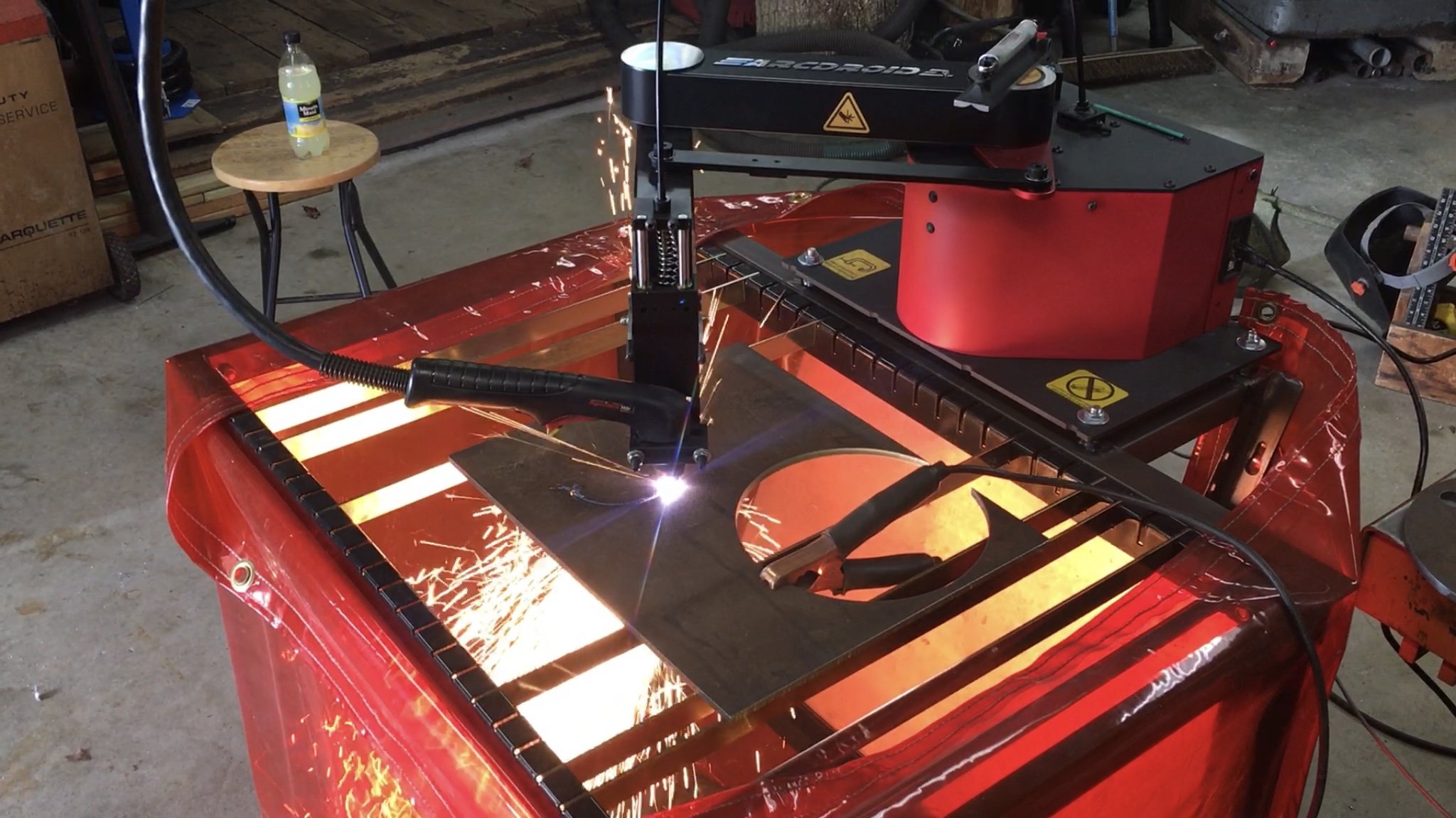

Things are once again afoot in Bob's workshop! What do you think he is making on the CNC plasma cutter this time?

What did Bob make? Why a table-top whistle stand for our beautiful new bronze whistle to be displayed! The whistle screws in with 2”NPT threads and three legs were zipped out with the new CNC plasma cutter in short order. After a bit of deburring and some TIG welding, the stand was complete. Going to look mighty fine with a whistle on it at our next public showing!

10/29/2022 Work Session

Wednesday, Brian and Hannah from Maine Locomotive and Machine were up and removed more superheater flues. These proved difficult to haul out to the pile, so we had to get a little inventive about our strategy. Hand trucks for the win!

The boiler has several studs screwed into it that hold things like the cab mounts, brackets that hold the walkways, air pump and other various appliances. Most, if not all, will require replacement, and it is important that their location, size and purpose be recorded. Leverett, our CMO, has begun the process of numbering, recording and diagramming the studs.

Present this week: Leverett, Hanna, Paul VS

10/22/2022 Work Session

Bob did a trial fit for the new cab front wall. While it wasn't a perfect fit right off the bat, the issues should be easy to address. With winter fast approaching, Jim took advantage of the last of the warm weather to get the tender doors and covers finished with a coat of black paint. Paul weatherized the tent with the addition of new shop skirting.

With the Downeast Scenic Railroad (DESR) operating season officially over, NESCo volunteers joined DESR to celebrate another successful year with a pizza party. Thanks to all who came out this year to support both operations!

Present: Paul VS, Bob, Jim

10/19/2022 Report from Bob DeWachter's Shop

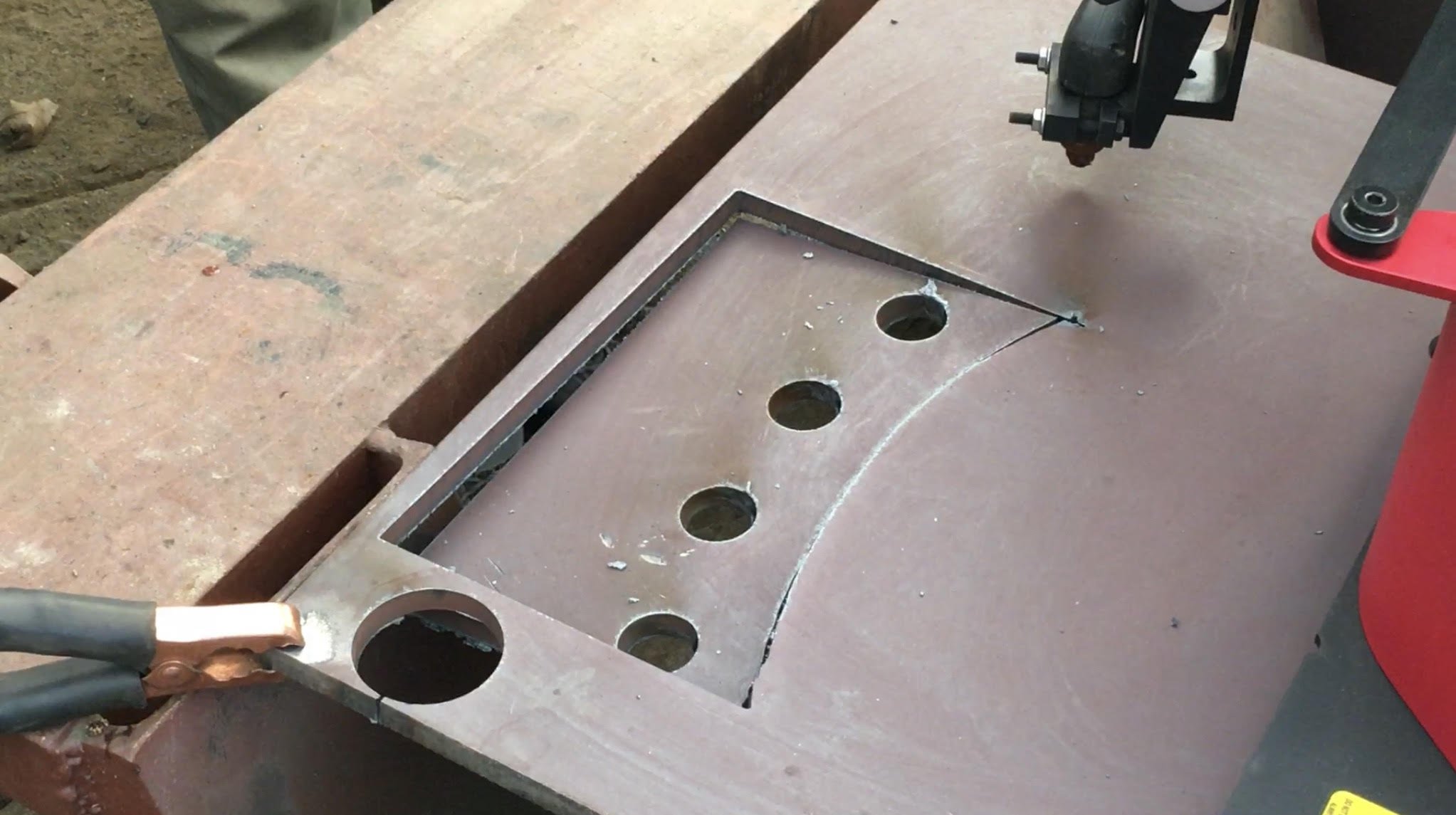

From the home shop of Bob DeWachter comes, new rapid metal fabrication! Using

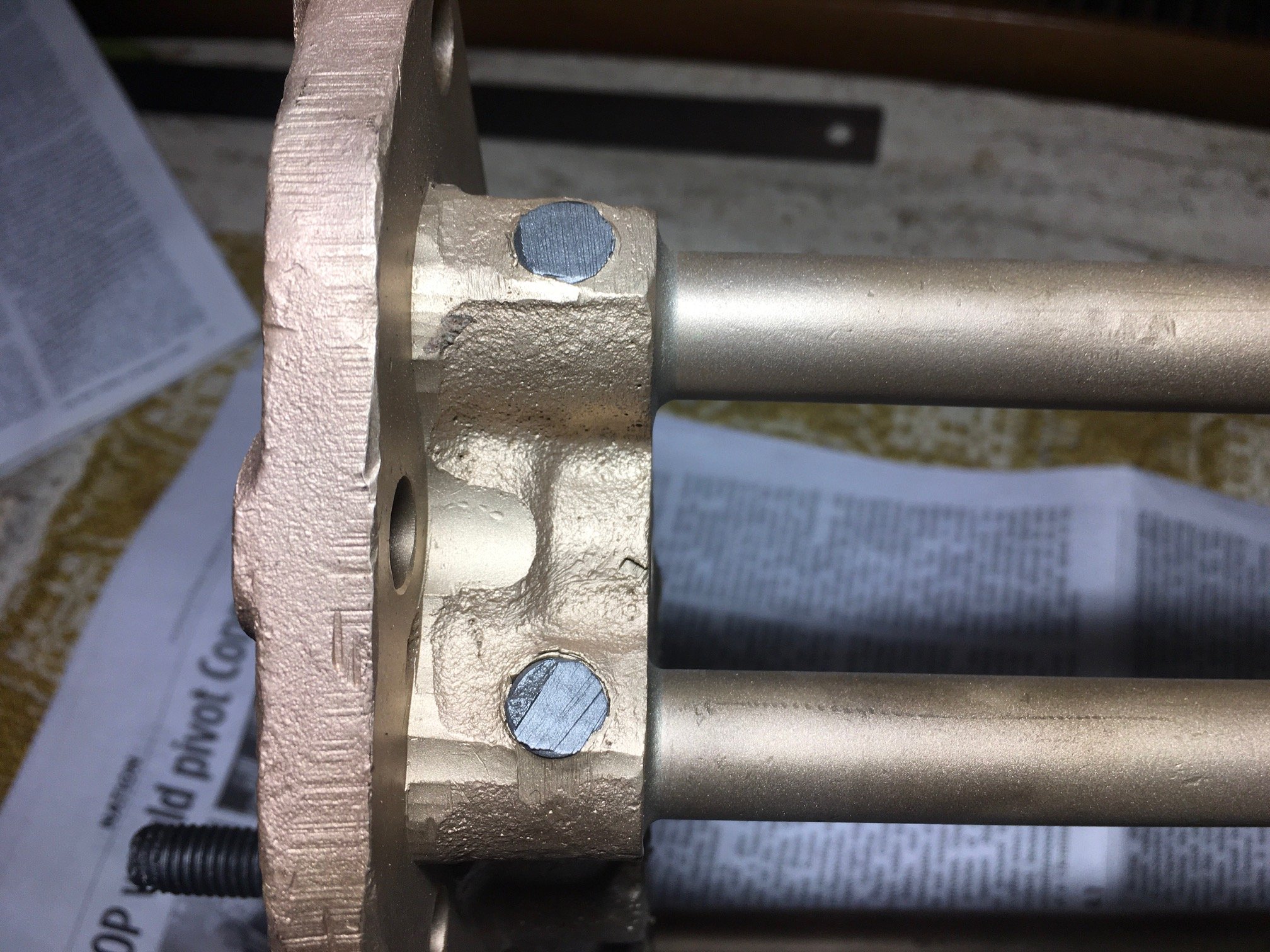

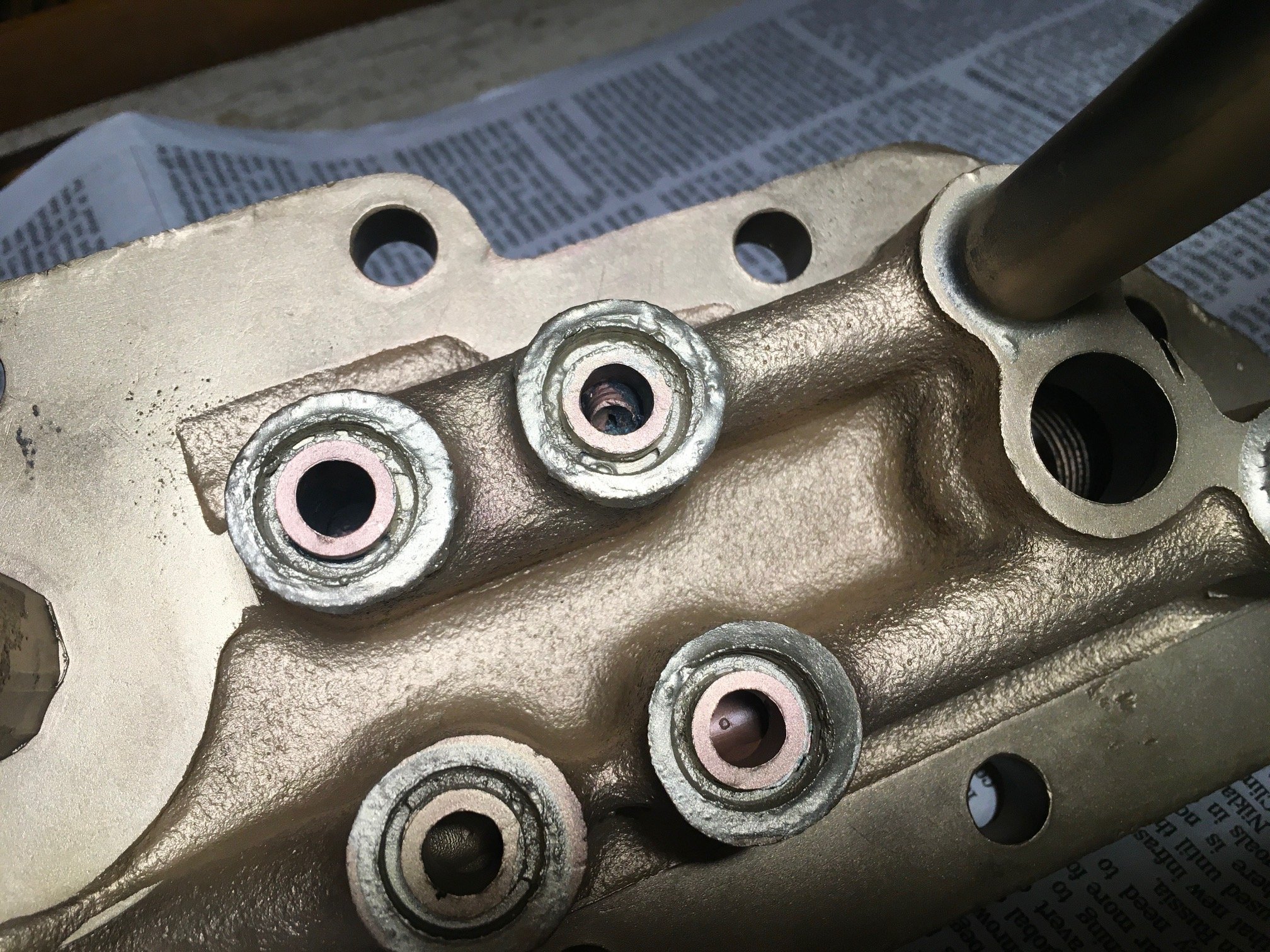

his new CNC robotic arm plasma cutter, Bob fabricated two pipe flange backing plates to install the water connections on 470's new cistern. These plates sandwich the tank floor and allow installation without holding wrenches inside the tank and prevent any seepage around the bolt heads. The CNC cut from 1/4” steel plate at 60 inches per minute and took about 1:20 min to accurately cut the center hole, four 3/4” bolt holes and the outside diameter. A few moments cleaning up and Bob was ready to weld the bolt heads to the plate.

This plasma cutter is small and portable, and will allow rapid fabrication of most anything from metal stock. It really opens up possibilities for us and we are excited to explore where we can use it next!

9/25/2022 Work Session

A small but mighty volunteer crew of two worked this Saturday, enjoying the beautiful, breezy early fall day. Paul VS single handily lugged the third batch of boiler tubes out to the storage rack. The boiler is nearly empty of flues and the pile is getting big!

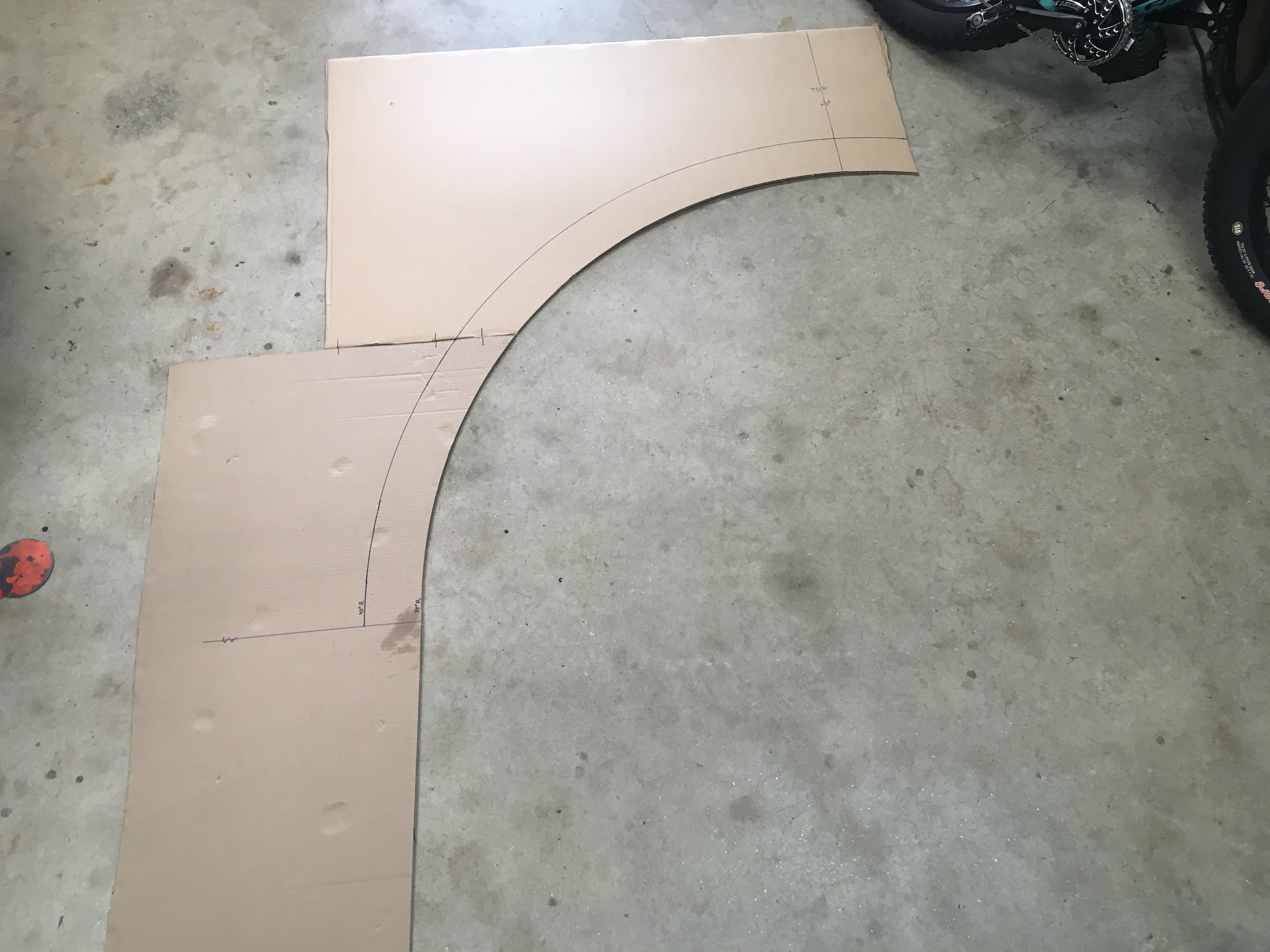

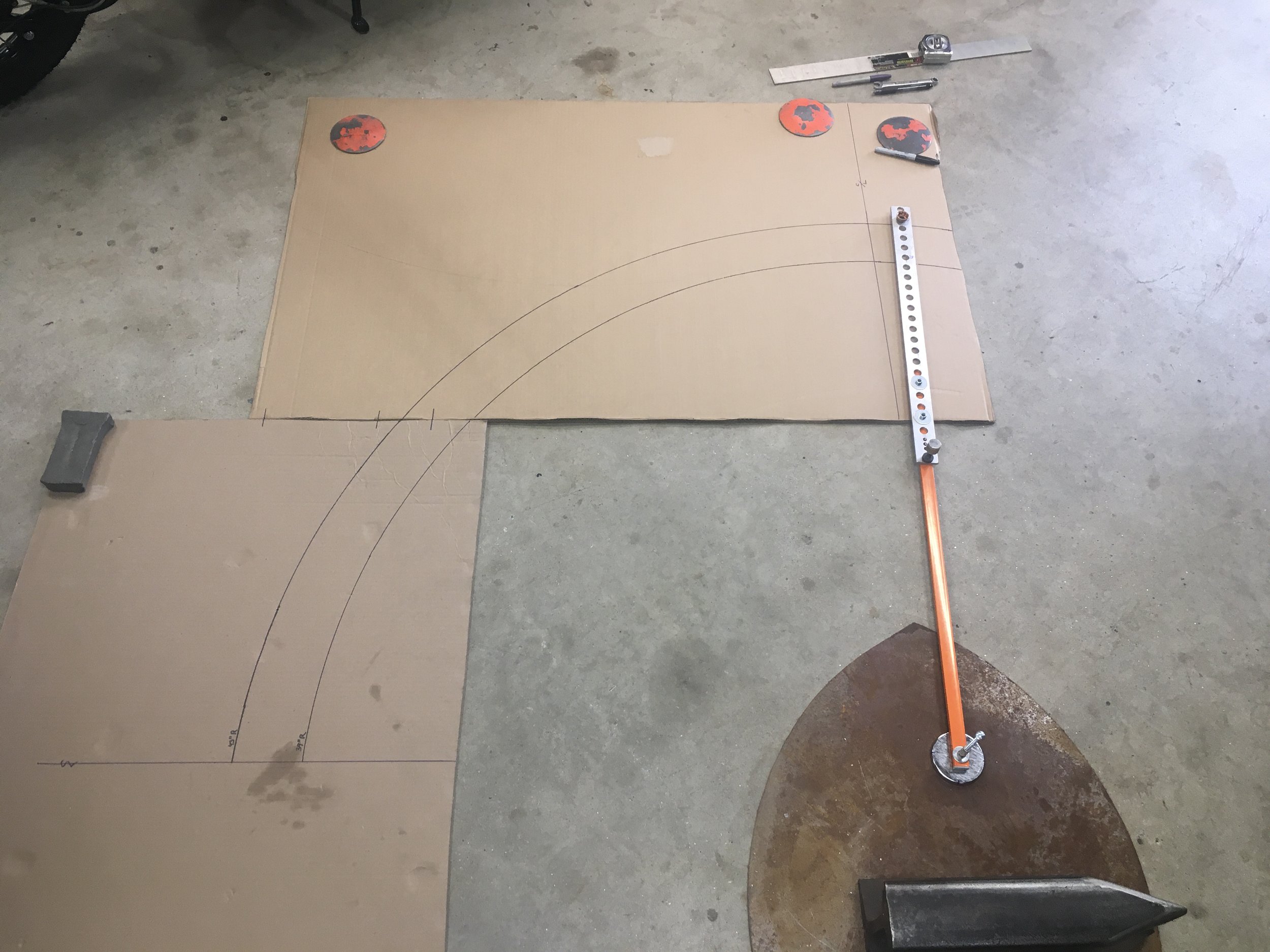

Paul and Bob then set up the new front cab wall sheet so that the outline of the boiler could be laid out and cut with a plasma cutter. The cut went well using a jig to guide the arced path of the torch. They reduced the diameter by one inch to allow margin of error for final fitment.

Present: Paul VS, Bob

9/10/2022 Work Session

Maine Locomotive & Machine Works cut out another large batch of boiler tubes over the last week. We added the tubes to our growing pile outside of the shop, clearing the way for more to be removed in the coming weeks. Check out how empty it's getting inside!

Work has also continued on the tender. The water outlet was drilled in the bottom of the tender tank (cistern) and all freshly cut edges on the new access panels have been ground down for safety. There is just a little more work to do before we coordinate with our crane operator to schedule the tender pick!

Present throughout the week were: Ron, Leverett, Hanna, Paul VS, Jim

9/4/2022 Work Session

About 1/3 of the tubes and flues have been removed thanks to the efforts of Brian Fansleau and Hannah Miller from Maine Locomotive & Machine Works. Our volunteers worked this weekend to move the tubes and flues into storage, so work can continue. These will be stored outside off the ground on some cribbing. So far there is pretty minimal corrosion evident! Leverett also begin the job of tallying up the boiler stud mounts and accounting for various brackets. It looks like every bracket stud on the boiler will be replaced. There are a lot of them...

Bob laid out and plasma cut the final and largest riveting access panel in the tender. It took three people to lift it out! With this panel access, we can now have access for the final water connection flange work.

Bob and Paul set up the cab wall spacer arch plate to plasma cut a narrow strip from it to permit a proper fit. This was cleaned up and clamped to the new cab wall. Jim and Alex used this as a guide to drill the next succession of rivet holes through the new cab wall.

Additionally, some shop clean up and rearrangement had to take place. First, the fabrication table had to get it out from under the cab. It was turned it sideways in front of the cab, so there is room to work on the front wall. Also, the stoker motor, in its storage crate, was taken to building 1 for winter storage.

There were some issues with the diesel air compressor throughout the work session. Leverett discovered the fuel pickup in the fuel tank was sucking air below 1/2 a tank. We will have to fix this, but at least we know when the tank is 1/2 empty now…..

Present were: Leverett, Bob, Paul VS, Jim Armstrong and Alex Fogg

8/29/2022 Work Session

Brian Fansleau and Hannah Miller from Maine Locomotive and Machine began flu and tube removal today on the boiler! The super heater tubes had been removed previously by NESCo volunteers in May 2022. This brings us one step closer to a completed boiler inspection!

470 Gets New Whistles!

As a contribution to the restoration of Maine Central 470, artist Bernie Perch has followed original Maine Central drawings to obtain dimensions, design, and machine two new bronze whistles for the locomotive. Each measures about 24" in height and weighs about 50 lbs.

The bronze began as a heavily damaged propeller off a fishing boat that was donated to NESCo. The 400-pound propeller was cut into smeltable chunks at the NESCo shop in Hancock, Maine, and these chunks passed through several volunteer hands to reach the Amish-operated Cattail Foundry in Lancaster, Pennsylvania. Using Bernie Perch's patterns, the bronze was poured into rough castings, which were returned to Bernie. Bernie did the machining at his home, producing this pair of gorgeous whistles.

The only departure from the original Maine Central drawings was the casting of "Maine Central 470" in the whistle tops and "NESCO" in the whistle valves, identifying specifically which engine these belong to. Bernie supervised the testing of the chimes on a steam line from a small steam switcher in Pennsylvania. People supporting the project included Susan Deupree Jones, Richard Glueck, and several friends of NESCo that acted as drivers between Maine and Pennsylvania.

NOTE: Bernie Perch is not in the whistle business, and is not soliciting requests for contract builds.

8/27/2022 Work Session

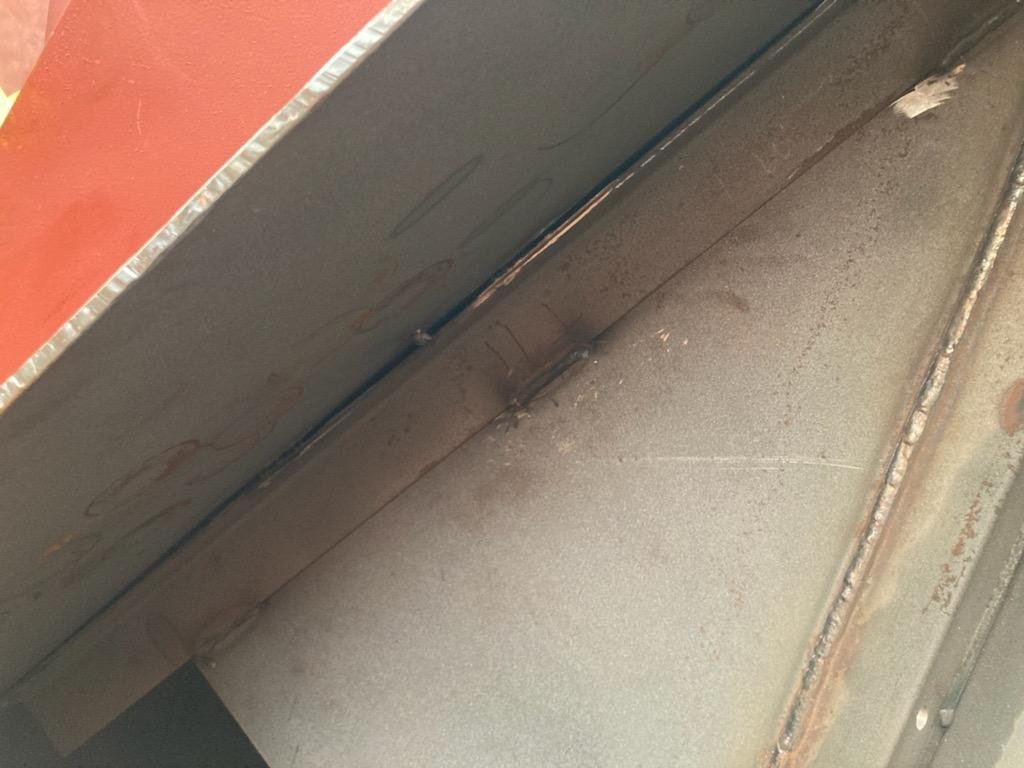

This weekend, our volunteers continued work on both the tender and the cab. They discovered that one of the tender frame water pipe brackets had a very poor weld done on it back in the day. This had to be corrected before the tender cistern can be lifted on the frame, so Jim ground out all the offending welds and corrosion. Bob rewelded two of the three sides, and then the repair was then primed and repainted. Jim also primed the tender's buffer plate and shim plate, along with the small tender access hatch. Paul worked inside the tender to grind out welds that tied the last access panel to a support brace.

Work continued to rebuild the cab front wall. First, the cab mounts were located and brought over to the boiler, so measurements could be made regarding the correct alignment of the cab front wall. Knowing how it all will go together, Bob re-examined the cab and discovered a minor error with a spacer, which will be corrected with some trimming. He then cut the arc of the new cab wall out.

In attendance: Bob DeWachter, Jim Armstrong, and Paul Van Steenberghe.

Prep for 8/27/2022 Work Session

In preparation for our upcoming work day on Saturday, Bob worked this week to make a couple of plasma torch guides. These will help us cut a new plate for the front of the cab. Last time, we tried to use the old front panel as a guide, but as you can see, the edges are pretty gnarly. Two guides were manufactured -- one is an adjustable fence that uses the edge of material as a guiding surface and the other is an arc cutter/ magnetic pivot with about 24”-46” range. This was tested on heavy cardboard at a 39” radius and a 43” radius. Let's see if we can copy this success in steel!

8/14/2022 Work Session

Enjoying a break from the blistering heat, we continued work this week on MEC #470's tender and cab restoration. Matt cut a flange clearance hole in one of the tender frame cross planks, allowing the water pipe to pass through cleanly when the tender cistern is placed on the frame. This takes us one step closer to our upcoming tender pick! Matt and Jim worked to clean another coal pocket door, as well as two of the compressed air tank brackets.

Bob and Hanna worked on the layout and cutting of the replacement front cab wall, using the old piece as a template for the new steel. They also drilled a mess of rivet holes which will hold the new front wall to the rest of the cab.

Present were: Bob DeWachter, Jim Armstrong, Matt Hofer, and Hanna Brooks