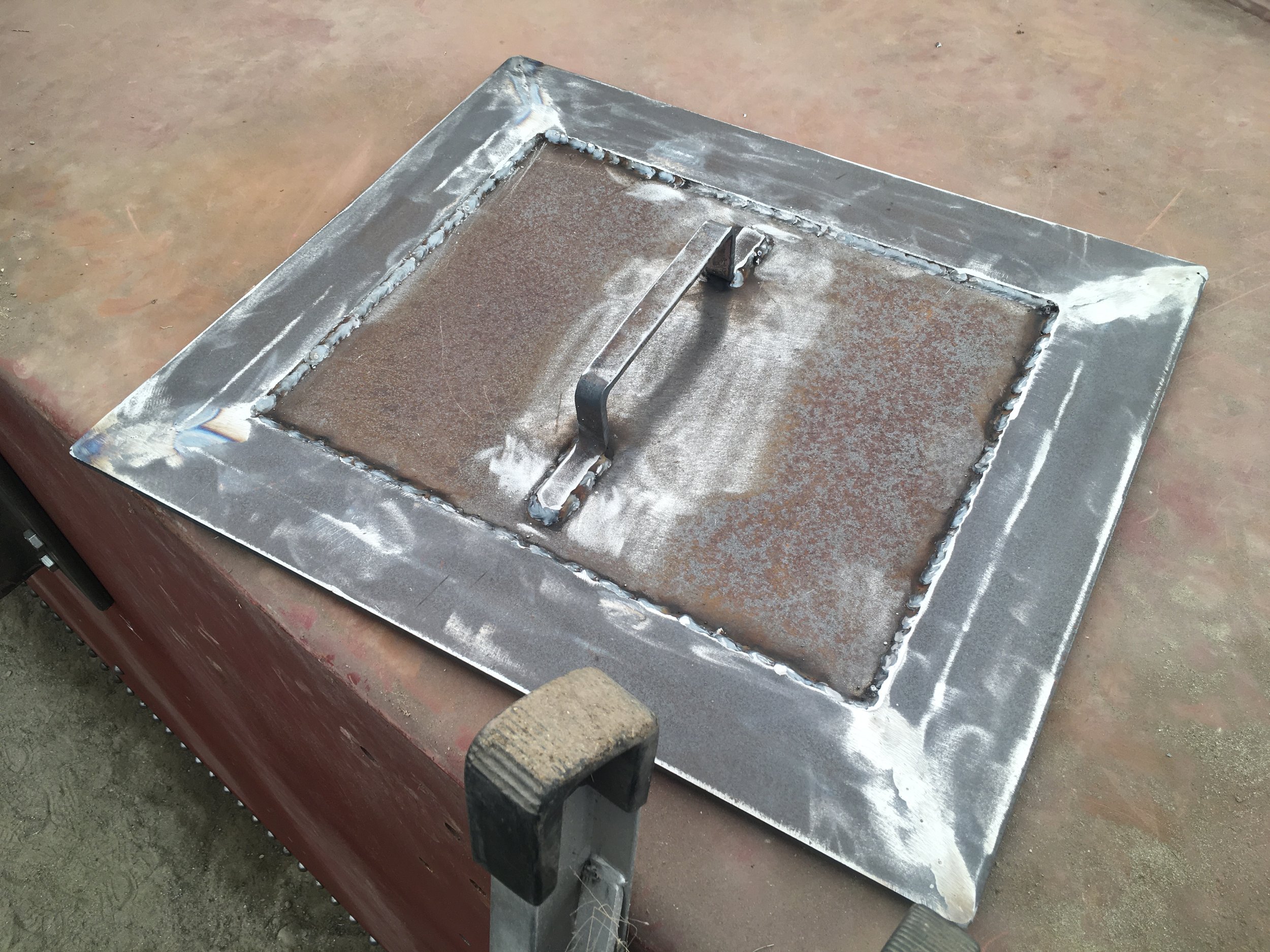

Ahhh!! Fresh air! Fabrication of the new removable cistern hatch was completed this weekend, allowing powered ventilation inside the tender cistern without restricting access at the manhole/ladder. Space is super tight up here and the extra inches saved in the manhole will be so valuable! Bob finished up the welding while Paul completed grinding of the opening to remove all the rough bits. Bolt holes still need to be drilled for permanent attachment to the cistern.

We also installed the rear cistern mounting brackets with new 1” diameter hardware. The location of these brackets was checked thoroughly, as these will be used to ensure the cistern positioning during the upcoming pick. Following the pick, these brackets will have to be removed and riveted to the tank a bit higher than the top surface of the frame. This will ensure that the cistern is pulled tightly against the deck.

The lateral tank positioning was checked a third time to verify it was correct. We are definitely flying with the motto: “measure a bunch, pick it up once”! Definitely want to get it right on the first try.

The tender pick is near to happening, with just a few tasks left to complete!

Present were: Bob DeWachter, Paul Van Steenberge, and Jim Armstrong