Work continued on the tender this weekend to prepare for the next stage of picking the tender up and placing it on the frame, as well as riveting. During the week, we traced out and drilled the required boltholes in the angle iron that will be used as lifting lugs during the pick. These have now been secured to the tender.

In order to make riveting possible throughout the tender, we cut a series of panels into the tender frame. A man hatch into the water leg behind the stoker compartment, which will eventually be converted into a bolted down hatch. An access panel was also cut out of the coal pocket to make riveting possible in this area. The other side of the pocket will also need to be cut. These panels will be welded back into place, and there won't be much evidence of this once we are done — none when a load of coal is in place.

We also worked to take apart the tender connection fittings in preparation for reconnecting these fittings to the new tender frame. Pictured is the mounting bracket for tender pipe connections after Brian disassembled and needlescaled it. Leverett and Al cut holes for the water flanges in the new tender body.

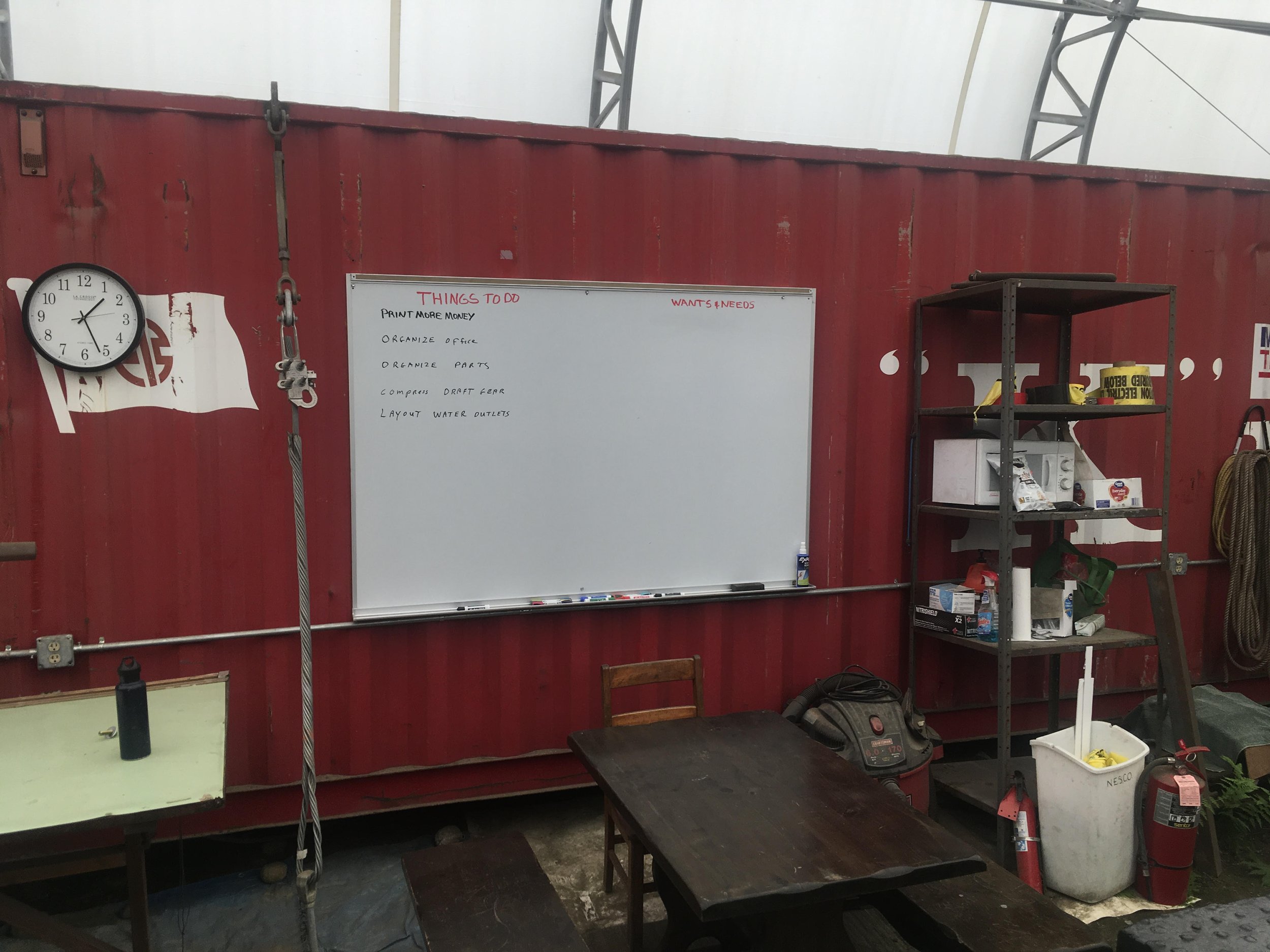

Additionally, this week, we installed a new “task” board in the shop and continued work on the Detroit Model A lubricator. There are two seals in the lubricator that gave us trouble when trying to remove them and will need to be replaced before the lubricator can be put back together.

Present for work this week: Bob, Paul VS, Brain H., Leverett, Al, Ron, and Hanna