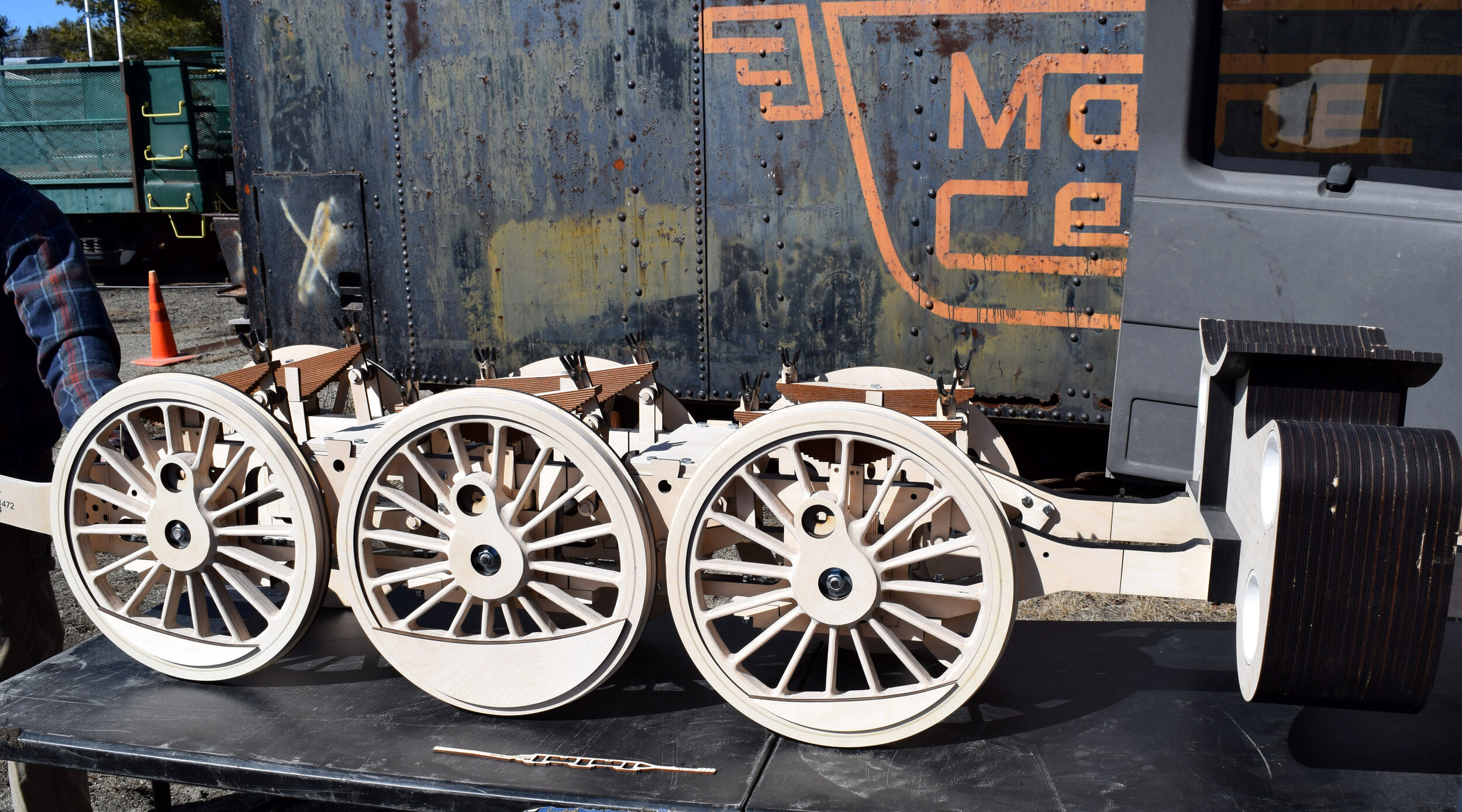

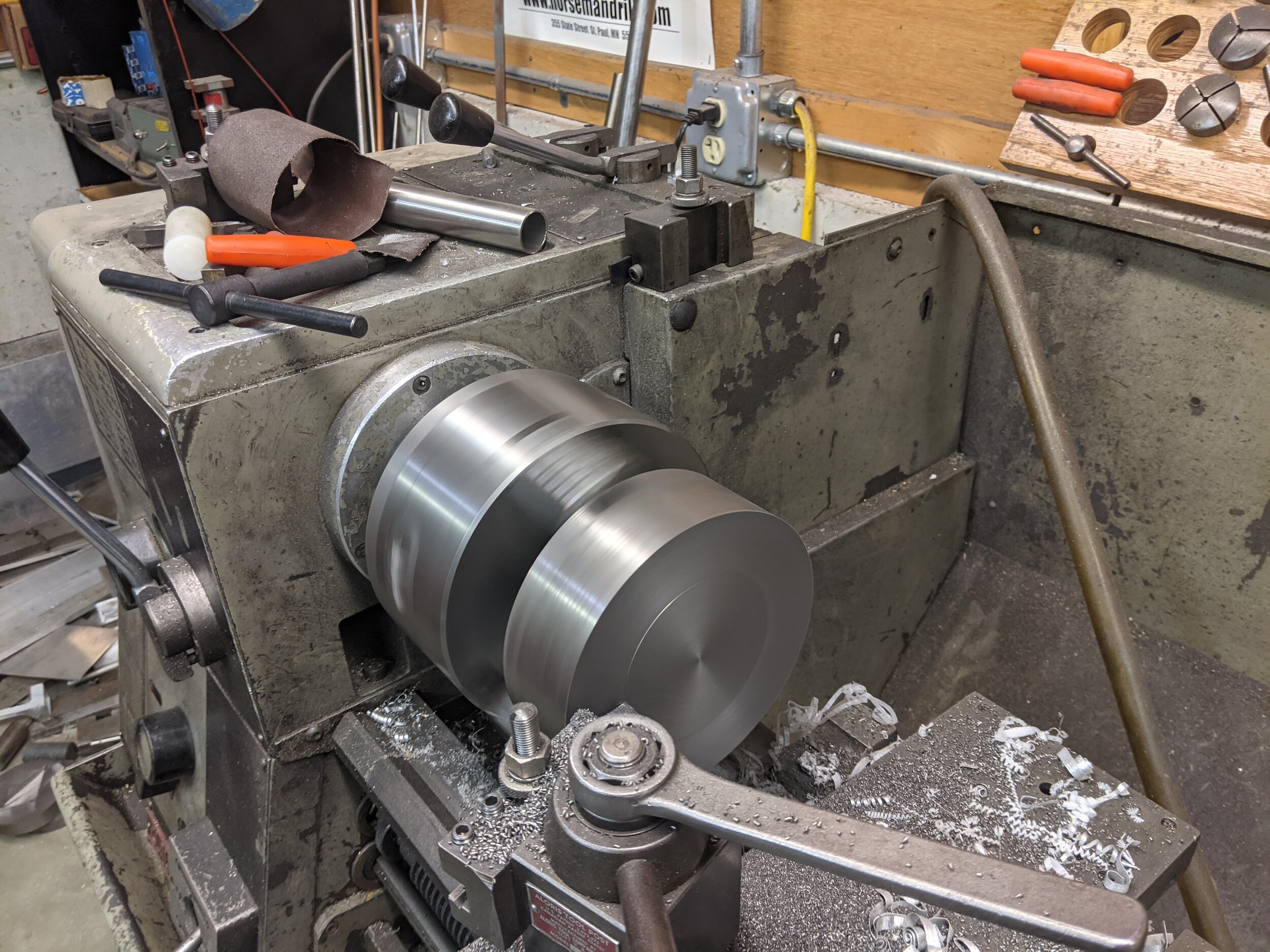

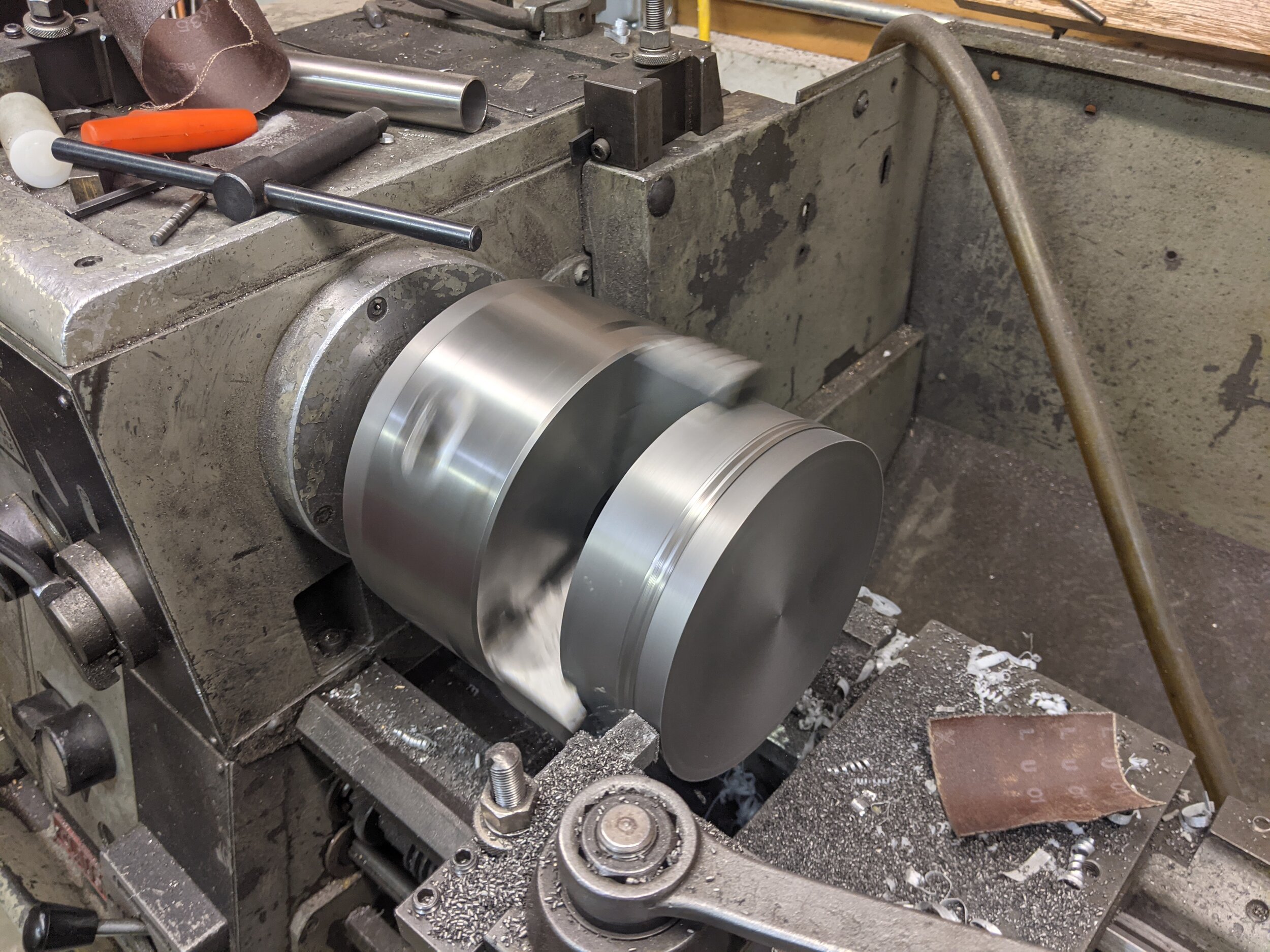

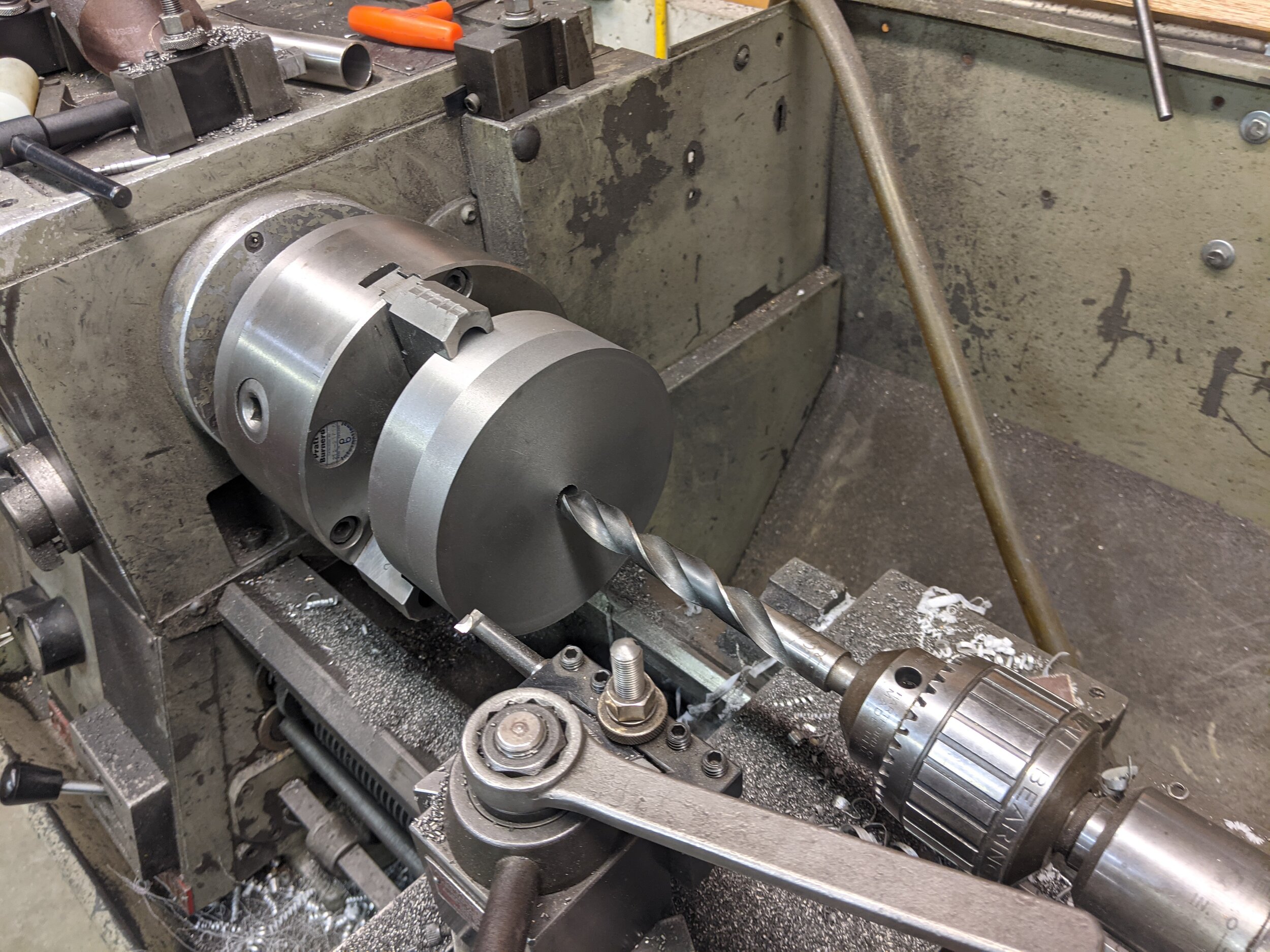

A special note was the return of Hanna and Roger B., both of whom have been out with extended illnesses (not Covid related). These are representative images from today's work, but not all the images taken.

Bob D. made it up today and trimmed a little of the old steel from the original cab side, then engaged Roger, Hanna, and me while he used the hoist to place the new fireman's side. It really looks good, clamped in place, although riveting will come a bit later.

Roger needle scaled the marker brackets and several handrail stanchions from the original tender. Hanna applied Lead-Out paint stripper to the original coal board trim off the old tender, and then moved on to do the same for several other appliances, including the mechanical lubricator box and the speed indicator wheel.

Peter Violette made it up and disconnected several lubricator lines from the frame, just ahead of the drivers. Peter later went on to help drain water which had collected on equipment stored outside, and also to grind away rivets holding the tender mounting brackets.

Our two newest volunteers, both from the University of Maine College of Engineering, Alden Burns and Cully Richard, removed 72 flexible staybolt caps from the right side of the firebox. Dick used a cutting wheel to slice away four sheet metal spacers, and then the three of us removed the various steam pipes from under the catwalk.

If there was ever an illustration for the new cab steel, check out this photo showing the newly constructed cab left wall and the rear wall which is going to be replaced.

As mentioned before, Roger Bennati was able to make it in and help clean rust and paint from significant parts off the old tender.

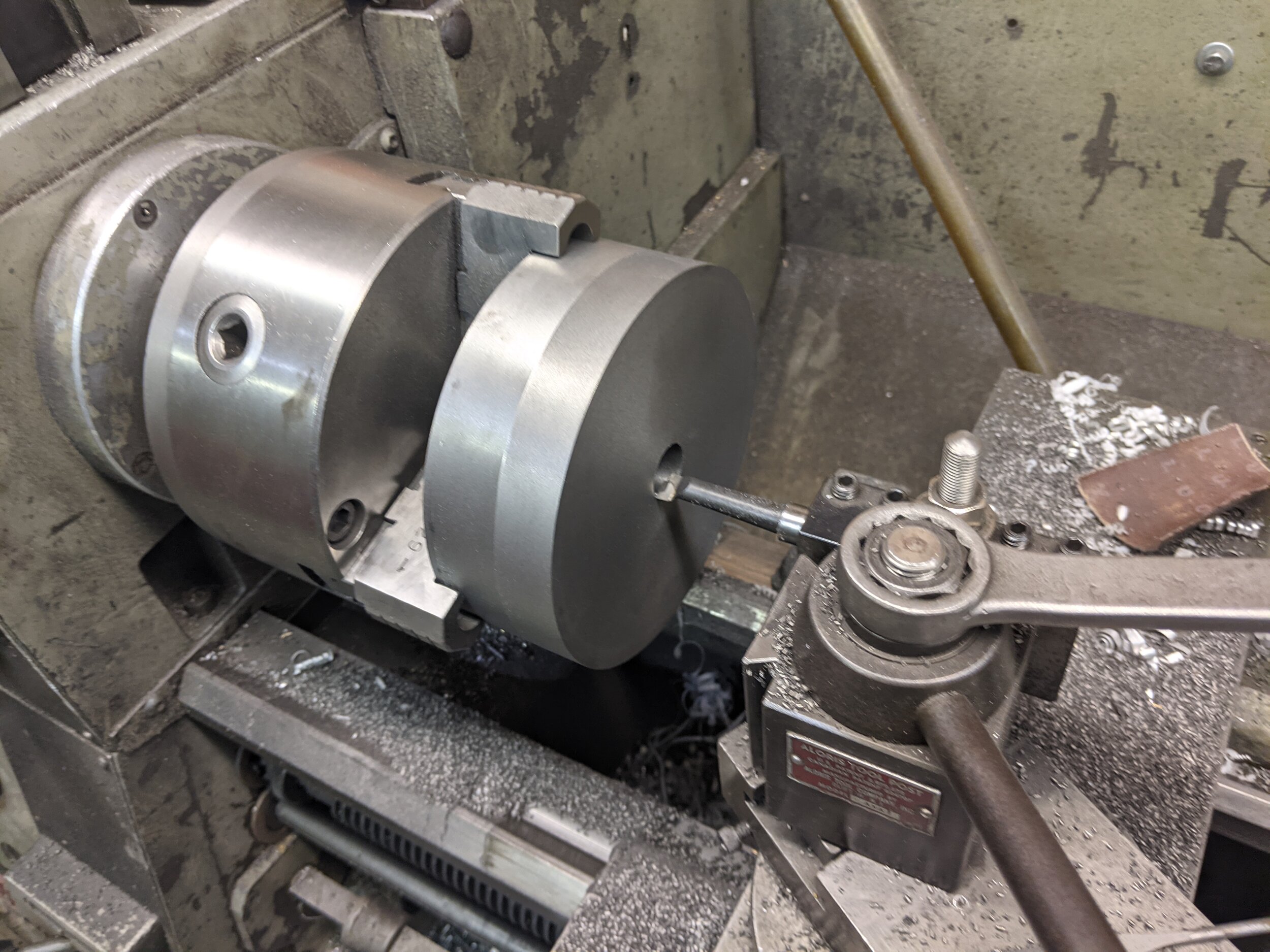

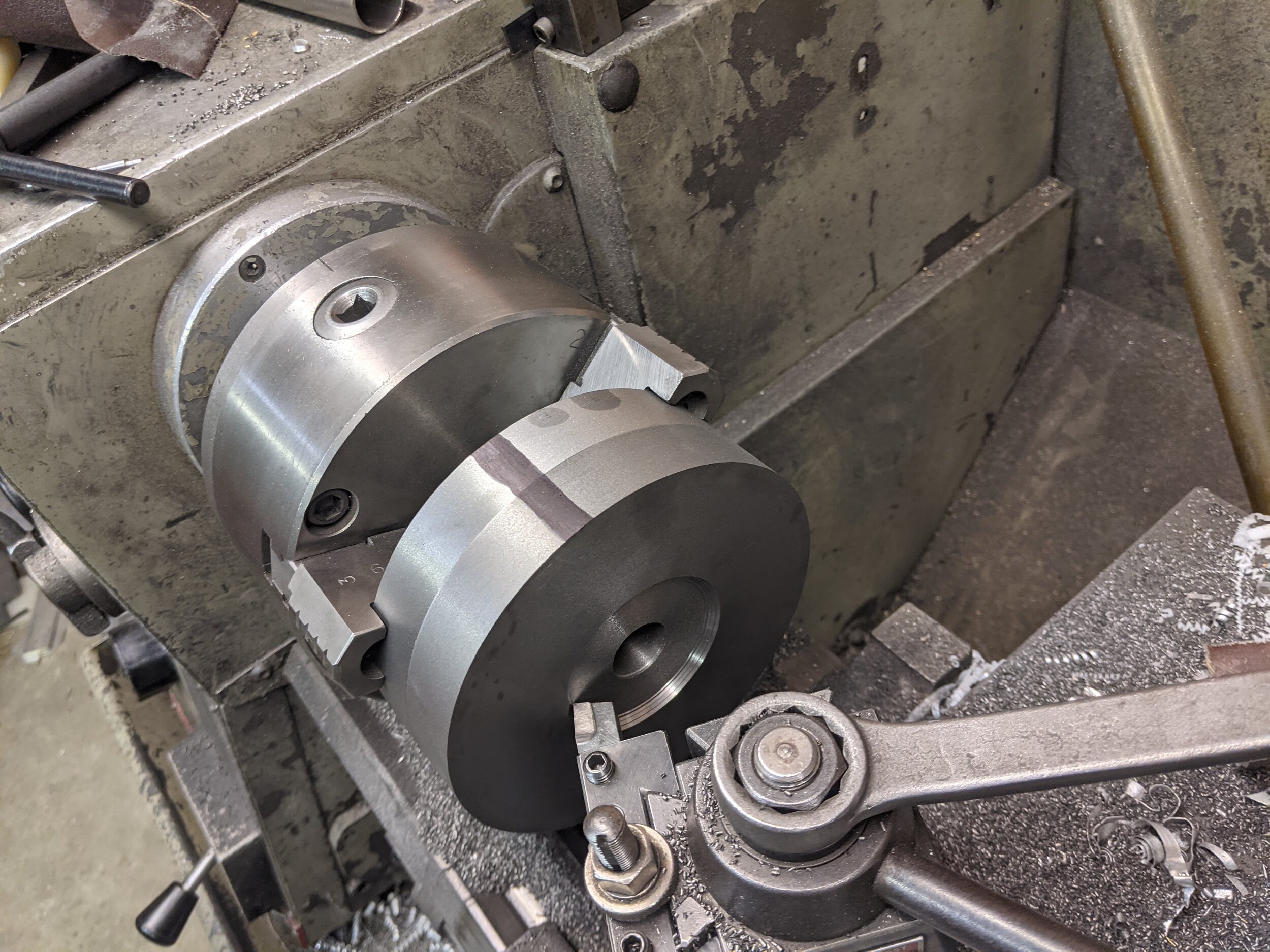

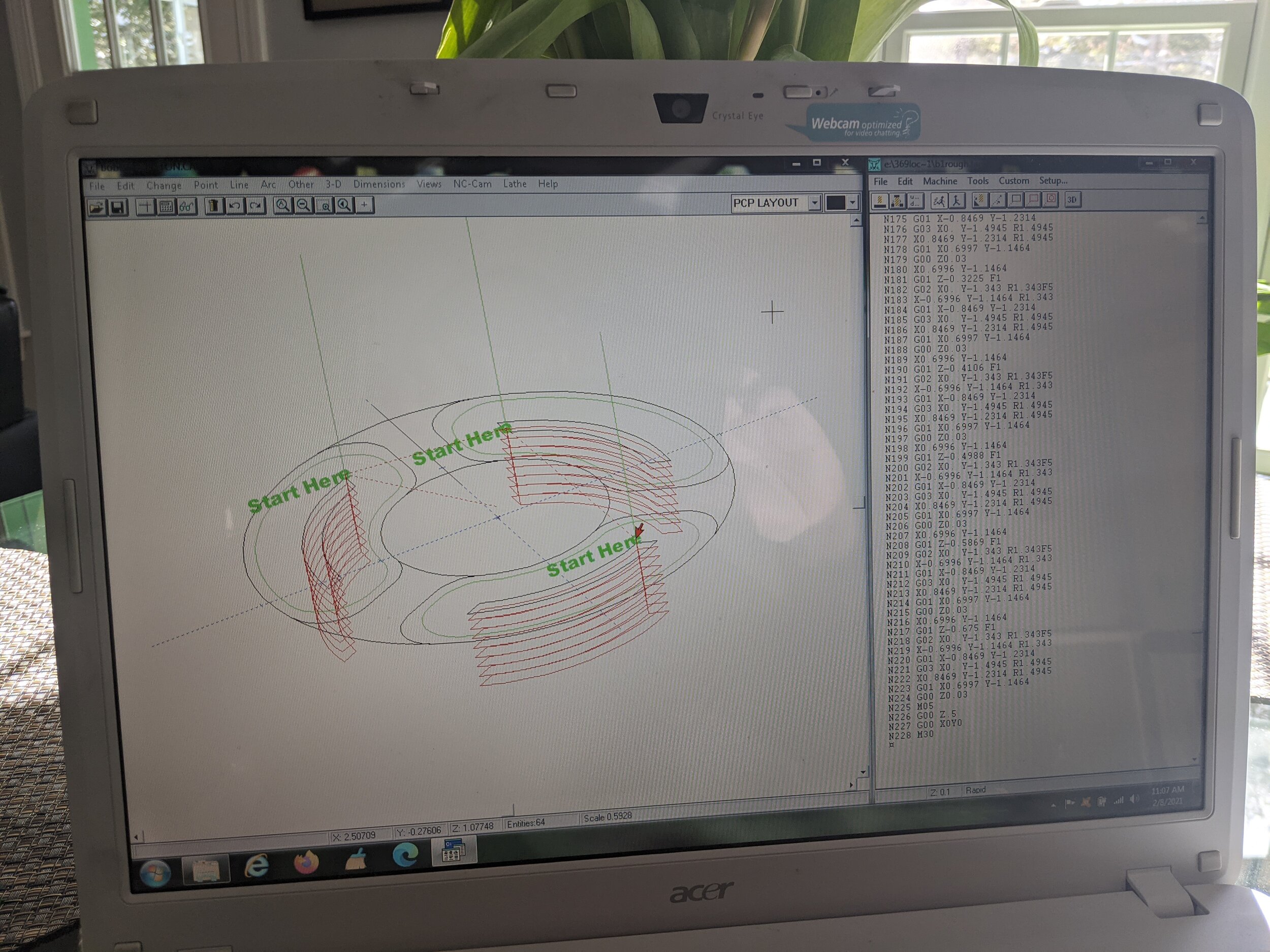

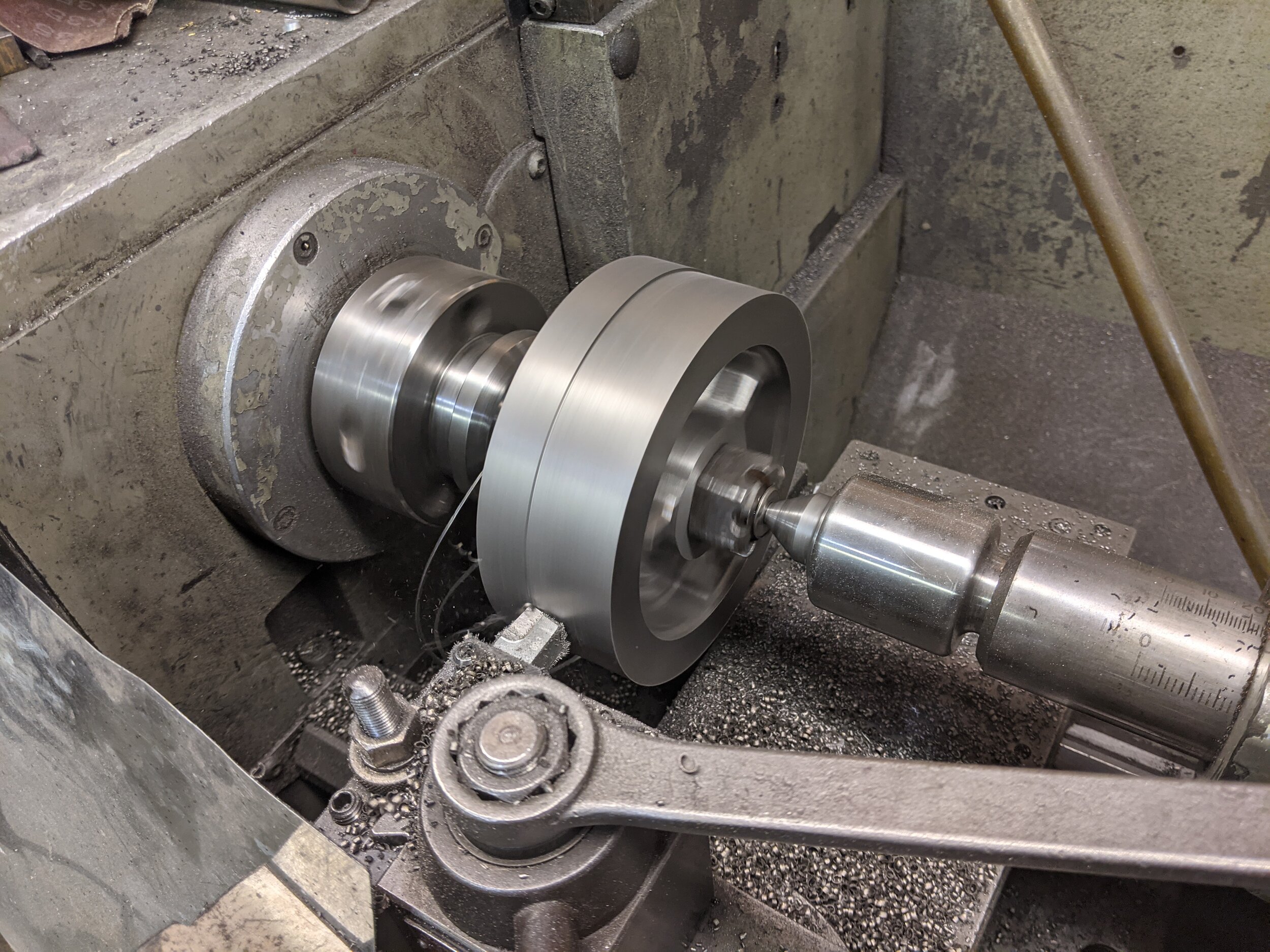

Last, but certainly not least, Ron Jenkins and Tim Steele have spent several days mid-week to drill out the holes where rivets will tie the tender tank ribs to the tank sides, in the old-fashioned manner.