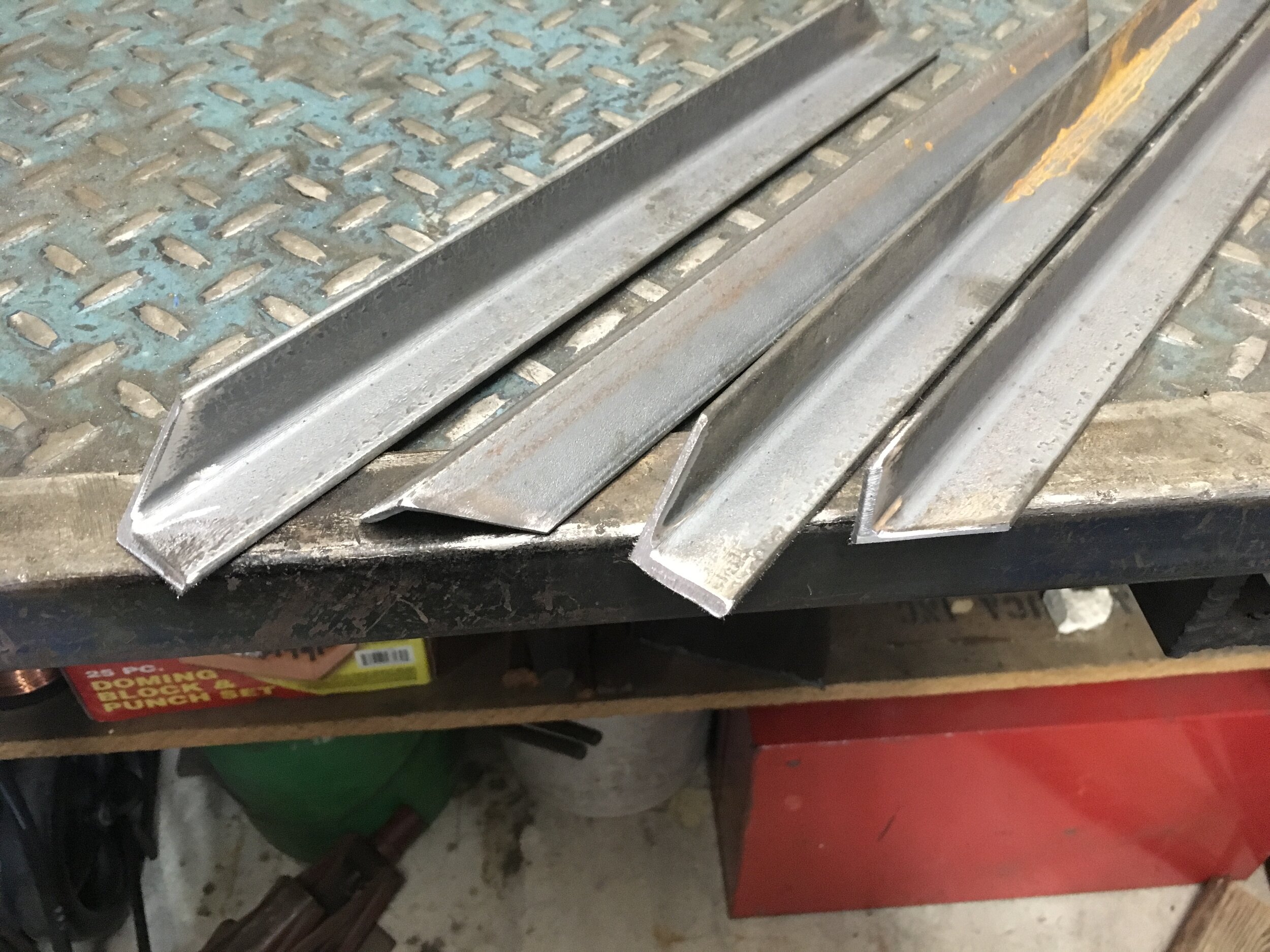

Exceptionally gratifying work day at the shop! Ron Jenkins showed us the rivet template constructed by volunteer Richard Otto, and used it to precisely locate and punch the locations of the rivets which will tie the interior bracing to the tank itself. Mr. Otto has been a solid supporter in the past year, and this particular tool was another donation which surpassed expectations.

Bob DeWachter and Ted Warren got the cab sections moved into place, then set up a hot practice run to sharpen riveting technique. Our newest volunteer, Alden Burns, a UMaine engineering student got into the thick of action alongside Paul Van Steenberghe, Alex Fogg, and Dick Glueck. The team switched from practice riveting, over to putting angle steel onto the cab sides. By the close of riveting, both engineer's and fireman's cab sides were ready to be fitted and trimmed. The two sides will be bolted in place and similarly hot riveted to the original cab roof.

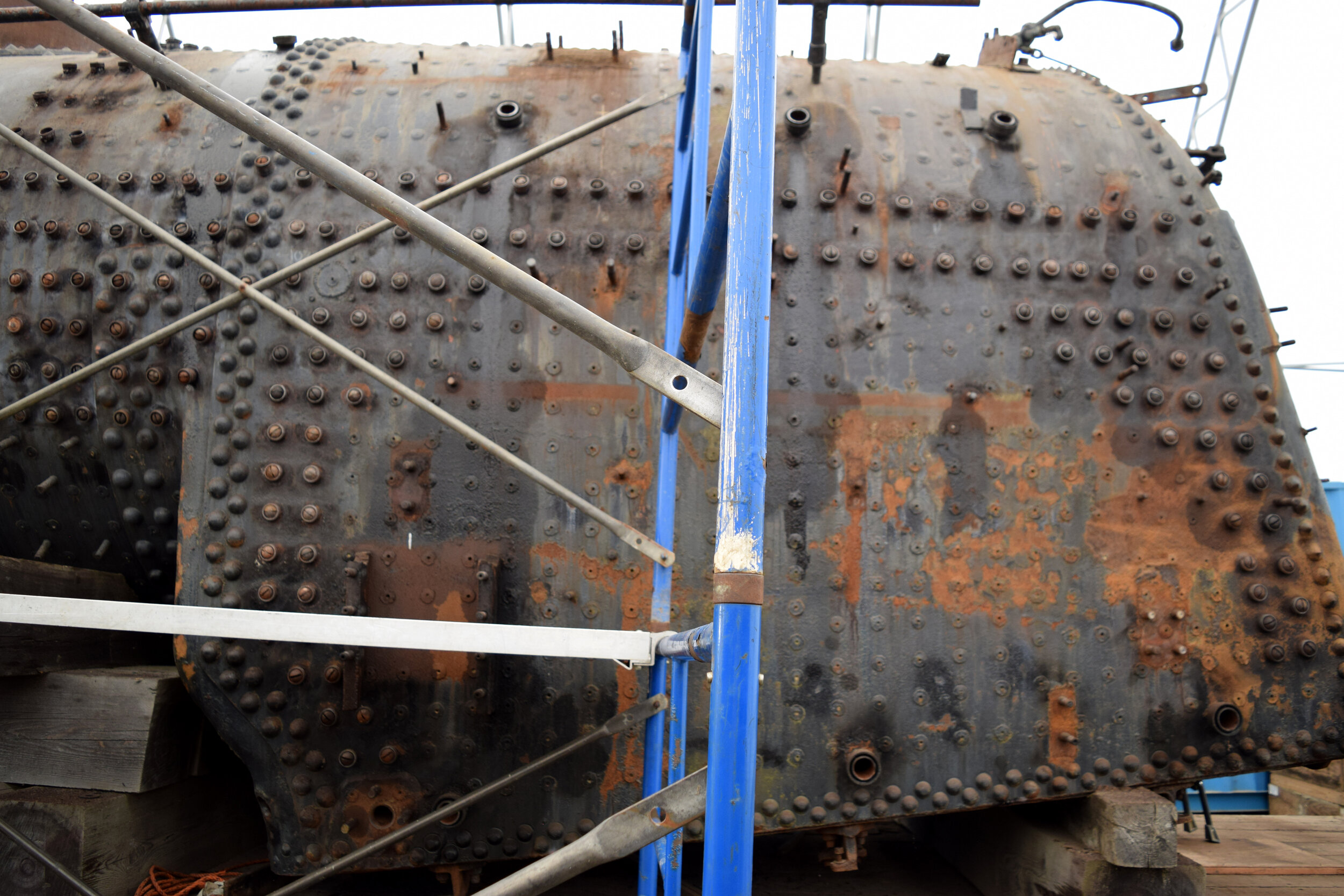

Alden and Dick worked on further removing items from the firebox, including three washout plugs, nine staybolt caps, the booster regulator bracket and the turbogenerator shelf. The left side of the firebox is nearly cleaned of items which haven't moved in seventy years. Leverett Fernald, Jim Armstrong, and Alex Fogg, have put considerable time into the firebox and backhead as well. Next week we hope to loosen up the throttle bracket and clean the top of the wrapper sheet.