Copia finished sandblasting the tender frame today and wanted to paint and get completed. Dick inspected the frame and took pictures prior to painting. What you're seeing in this set is the frame completed, but still coveted in iron oxide dust and grit. The area which had the creosote or tar took them a long time to get clean, but clean it came. The deep pockets of sand, grease, rocks and all that jazz are gone, as are the areas of scaled iron oxide. The primer could have been any color, but we choose a charcoal gray. The primer is a quality covering , and the last pictures are of the primer being sprayed onto the frame. Tomorrow the tent and scaffolding comes down and goes back to the shop.

Tender Frame Sandblasting

Copia Specialty Contractors began sandblasting the 470's tender frame on Tuesday, May 5th. During an interlude in work, NESCo president Dick Glueck was permitted to inspect what had been accomplished. What you are seeing here is the coupler end completed, including the organic accumulation, glass, stones, inside frame pockets removed.

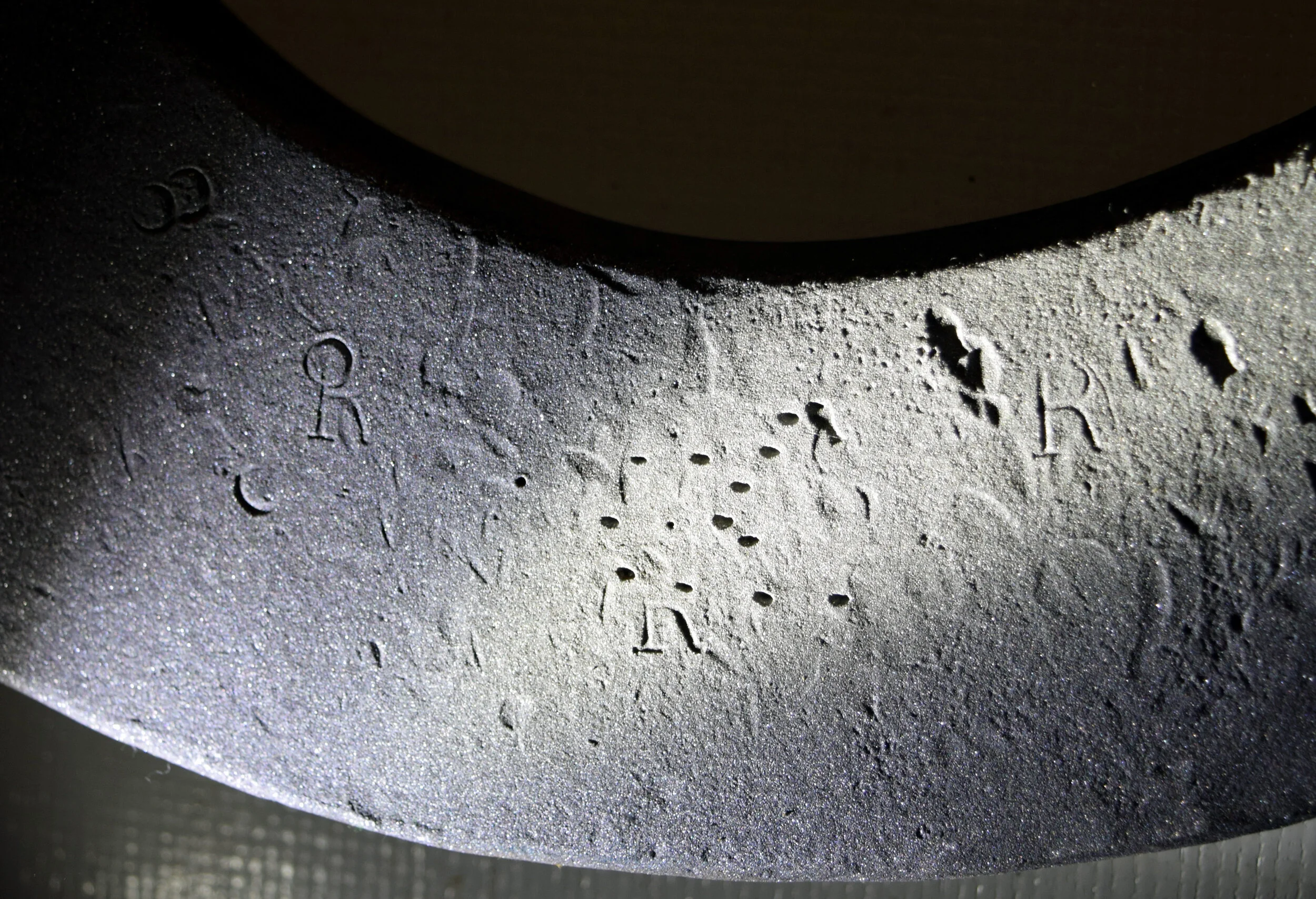

The metal that has been completed, including the underside, is gray, and only has a reddish tinge because of the particulates that have settled. The blasting has revealed a few tiny bubbles in the original steel casting, but nothing larger than a pencil point. As you can see, the blast tent is enclosed, including the floor. Tomorrow the technician is going to clean and tape over the truck pins and supports, then blast around them. Thursday should see the drawbar end completely cleaned. As soon as the dust is gone, they will be priming the whole frame.

4/18/2020 Tender Update

On Saturday, April 18th, President Dick Glueck and CMO Leverett Fernald took a trip up to Millinocket Fabrication & Machine to meet with President Ed Lewis and review the progress on the tender while the shop was closed for the weekend. Proper social distancing measures were taken to ensure the safety of everyone involved.

Mr. Lewis thinks the tender may be completed in a month. The plan is to lift it onto a flatbed and keep it inside until delivery. NESCo will have things ready in that period of time so as to unload it onto a manageable platform and get it indoors. Dick and Leverett were very impressed by the workmanship and the manner in which the tank is being finished. Decking may go on next week, possibly week after.

Each photo is labeled accordingly.

3/21/2020 Updates

1) Leverett is turning fitted bolts to replace those truck bolts which were beyond repair. He also refinished the worn and cracked pedestal side.

2) Ed Girsa from Millinocket Fabrication & Machine has sent more photos of further construction on 470's tender. Ed says the rolled corners will be installed this coming week.

3/18/2020 Tender Update

The COVID-19 pandemic has Mainers taking precautions as recommended by medical officials. Part of this includes temporarily closing work sessions and visitation at the New England Steam Corp. shops, as well as our co-operative partners at Downeast Scenic Railroad. What hasn't stopped, although closed to outside visitors for the time being, is work on the 470's new tender tank. Millinocket Fabrication & Machine is continuing work while protecting their employees. Here are three images of the tender as of March 18th. MF&M President Ed Girsa tells us the major components are just about finished, although the corners of the tank are to be rolled next. From that point forward, it's a matter of assembly. We are very appreciative of this high standard of work ethic and customer satisfaction during this upheaval in our nation's scheduled plans.

2/22/2020 Tender Update

What you see in the two images is the sandblasted floor of the new tender, along with some welding, done at Millinocket Fabrication. The inner baffles are completed. Oversize steel plates have been delivered and next week they begin to fabricated the tender sides. They work on it every day, but next week, they begin in earnest.

2/22/2020 Work Session

Small crew at the shop today; Bob, Paul, Al, Ron, Alex, and Dick. Ron retrieved some of the newly primed valve gear and also worked on more of parts. A picture of a few of the parts is included. Primer is working beautifully.

Alex and Dick did some re-arranging in the center red container, so the second work bench is now against the wall. More work needs to be done to set up the electric shop tool. Bob and Paul installed ceiling LED lights in the container, with a temporary, but effective power system.

Bob, Alex, Paul, and Dick worked on cutting a representative slice out of 470's cab. This will allow a metal shop in Newport to cut a pair of new sides, and curl the sides to match the old, damaged, steel, presently in place.

Paul oiled the nuts which hold the superheater tubes in place, as they've been problematic the last few times we've attacked them.

2/15/2020 Valve Gear Update

Ron and Dick picked up the valve gear from Copia Specialty Contractors of Bango, at 10AM on Friday, February 14th and brought it to the yard. The part numbers have been revealed quite nicely, and everything remaining on the surfaces has been eliminated. Parts will be inspected and marked with tags, then once the weather gets warmer, primed, sanded, primed again, and painted. It appears that everything remains in remarkable, serviceable condition.

2/14/2020 Tender Update

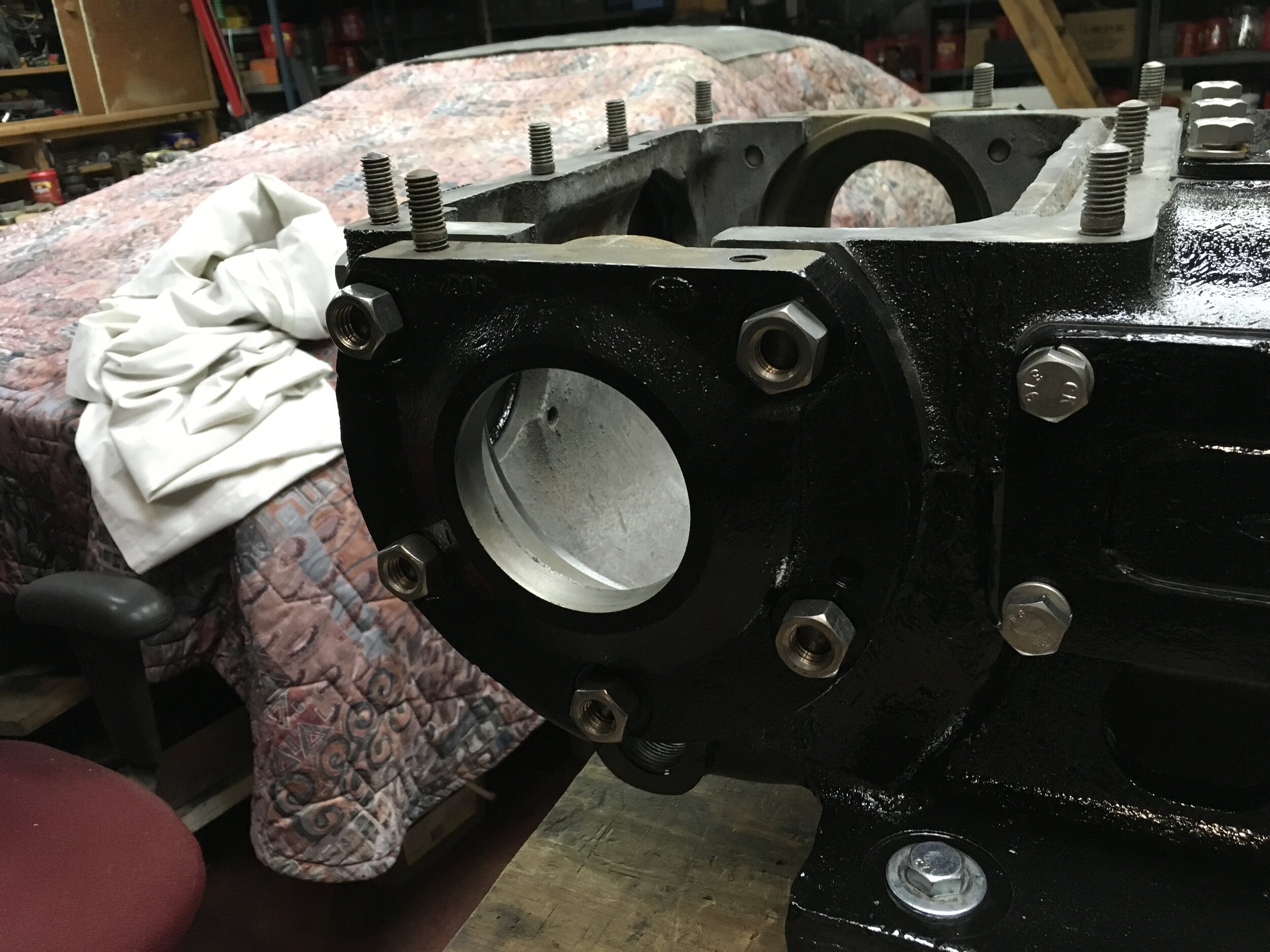

Millinocket Fabrication & Machine in Millinocket, Maine is constructing a new tender tank for 470. The first pictures of 470's new tender have just been received. These are the internal baffles to reduce the movement of water during acceleration.

The tank will have a welded interior and riveted exterior. Millinocket Fabrication & Machine will complete all welding and tack the exterior sheets. Once delivered, New England Steam will begin the process of setting rivets.

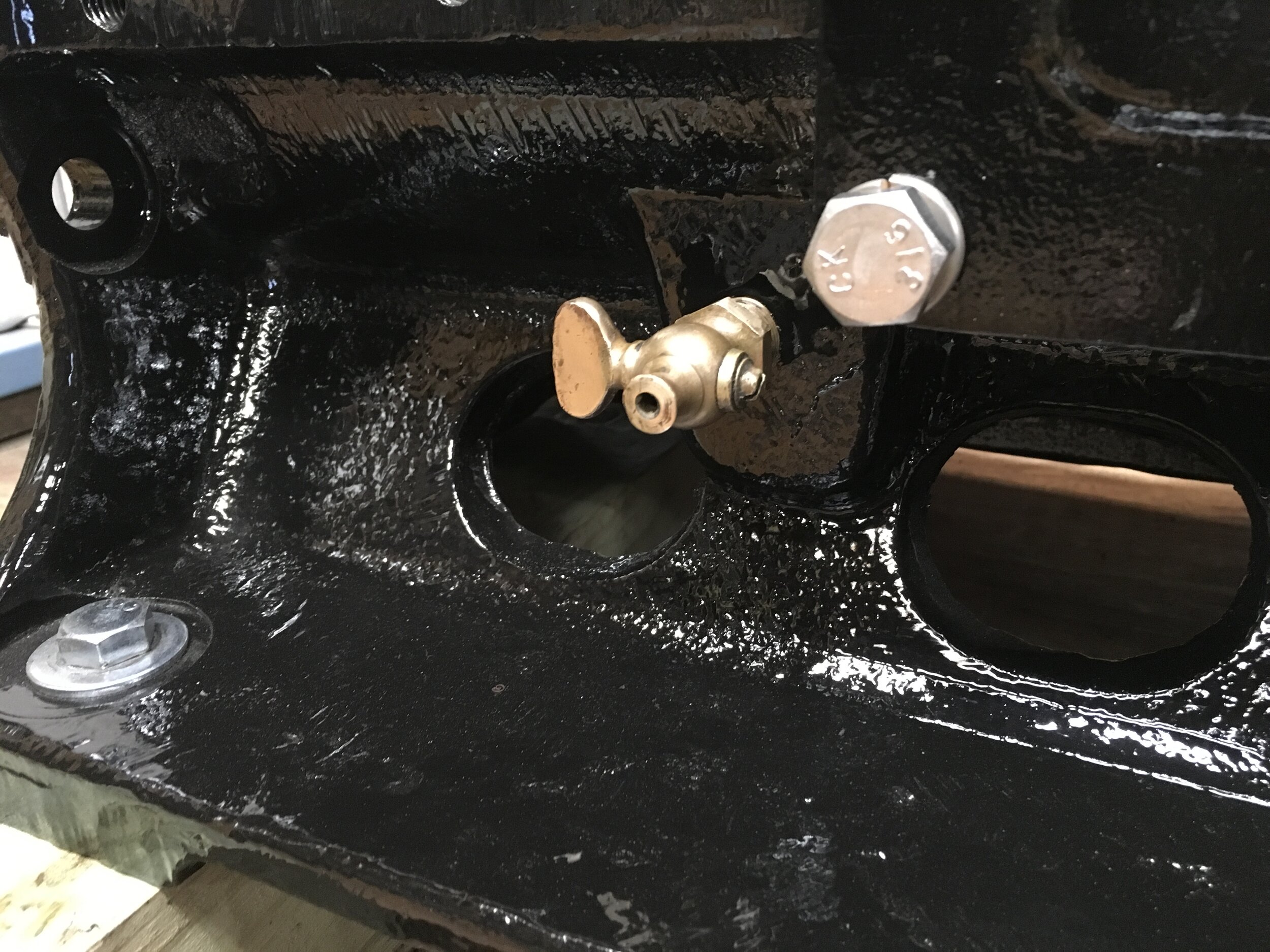

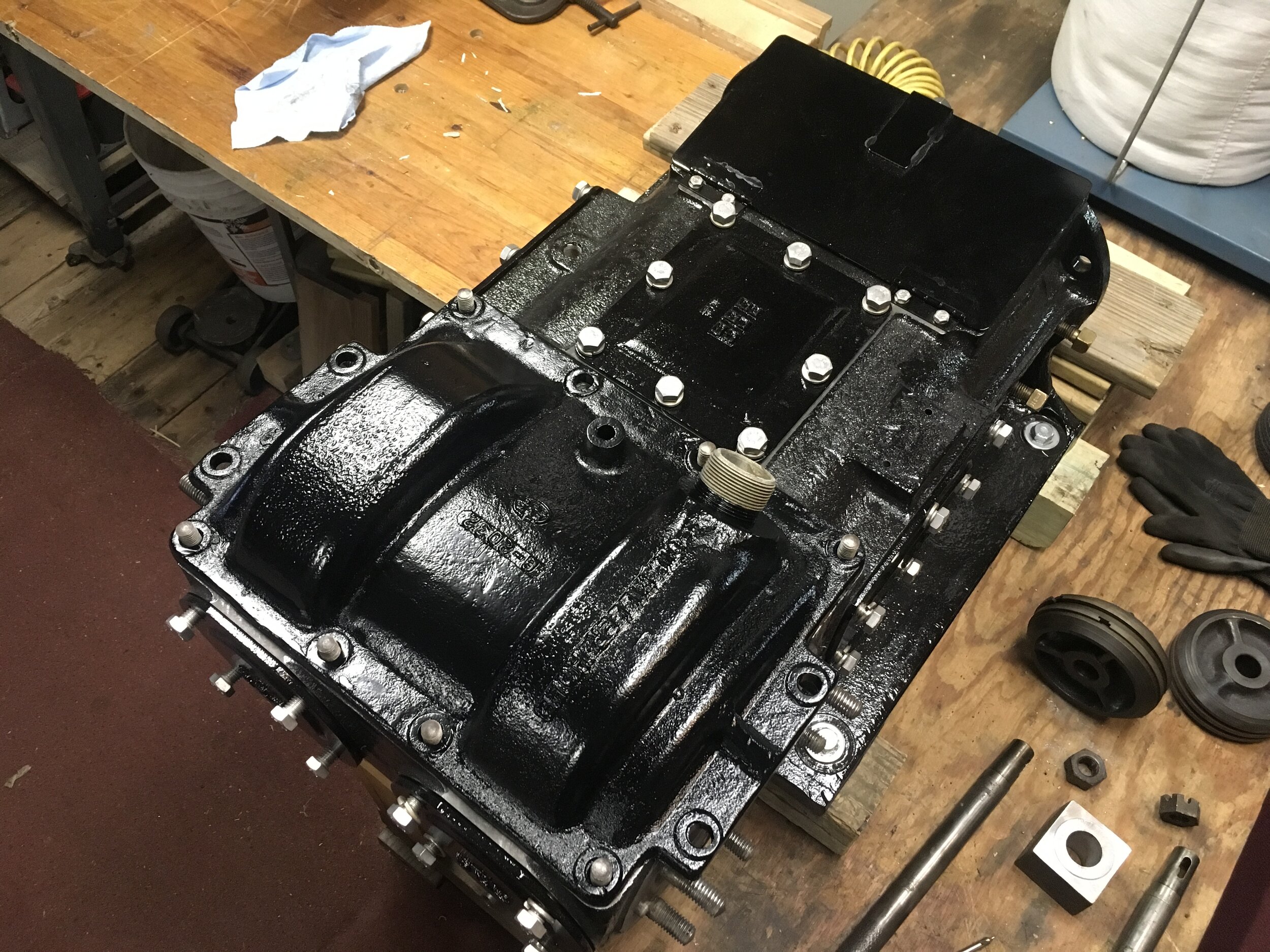

1/12/2020 Stoker Update

Bob DeWachter has been hard at work on #470’s stoker!

One of the missing items was the crankcase oil dipstick. Bob made one from scratch out of brass, with tapered cap fits snug on the cover boss. The flat in the rod is the oil level mark.

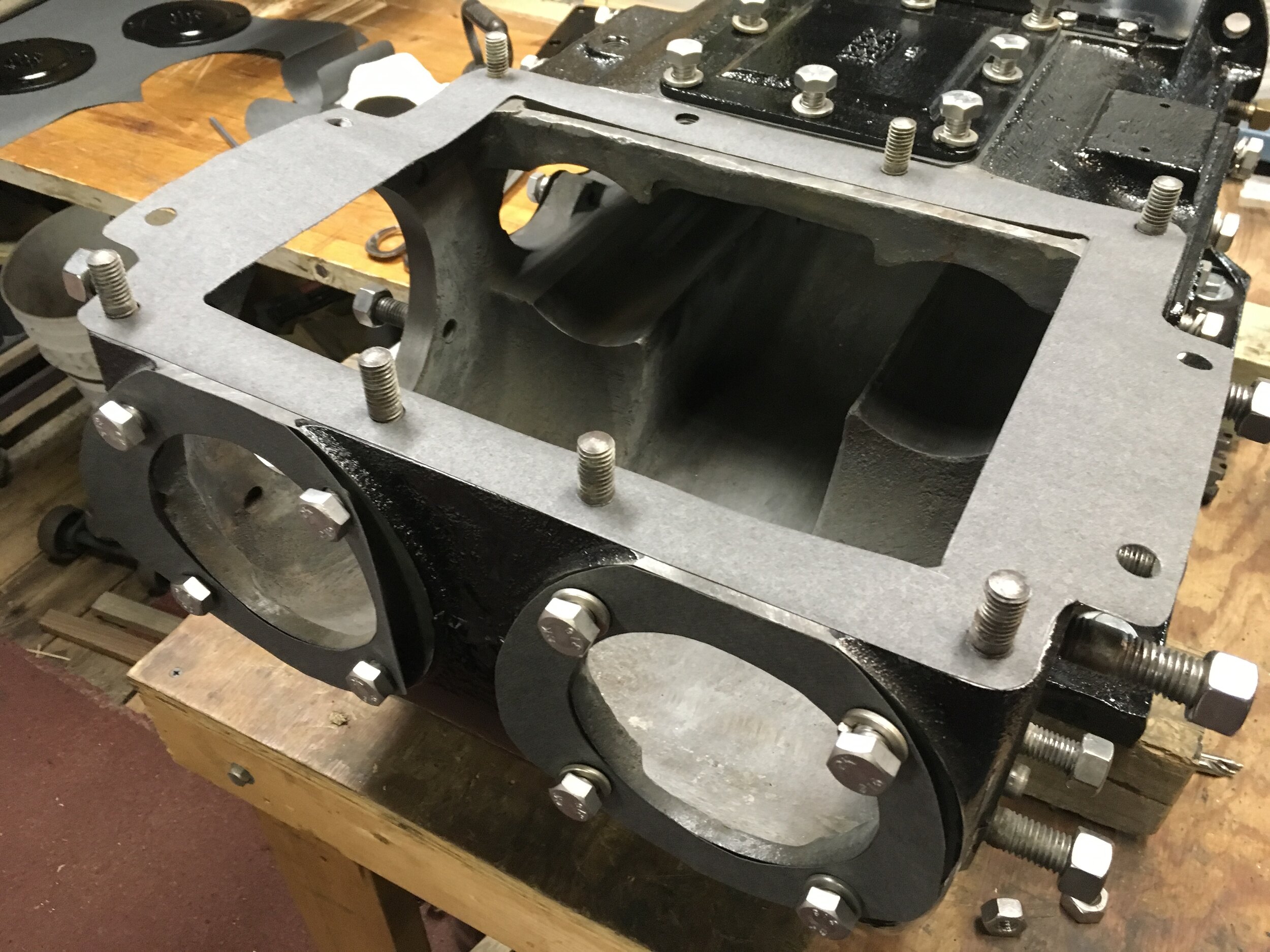

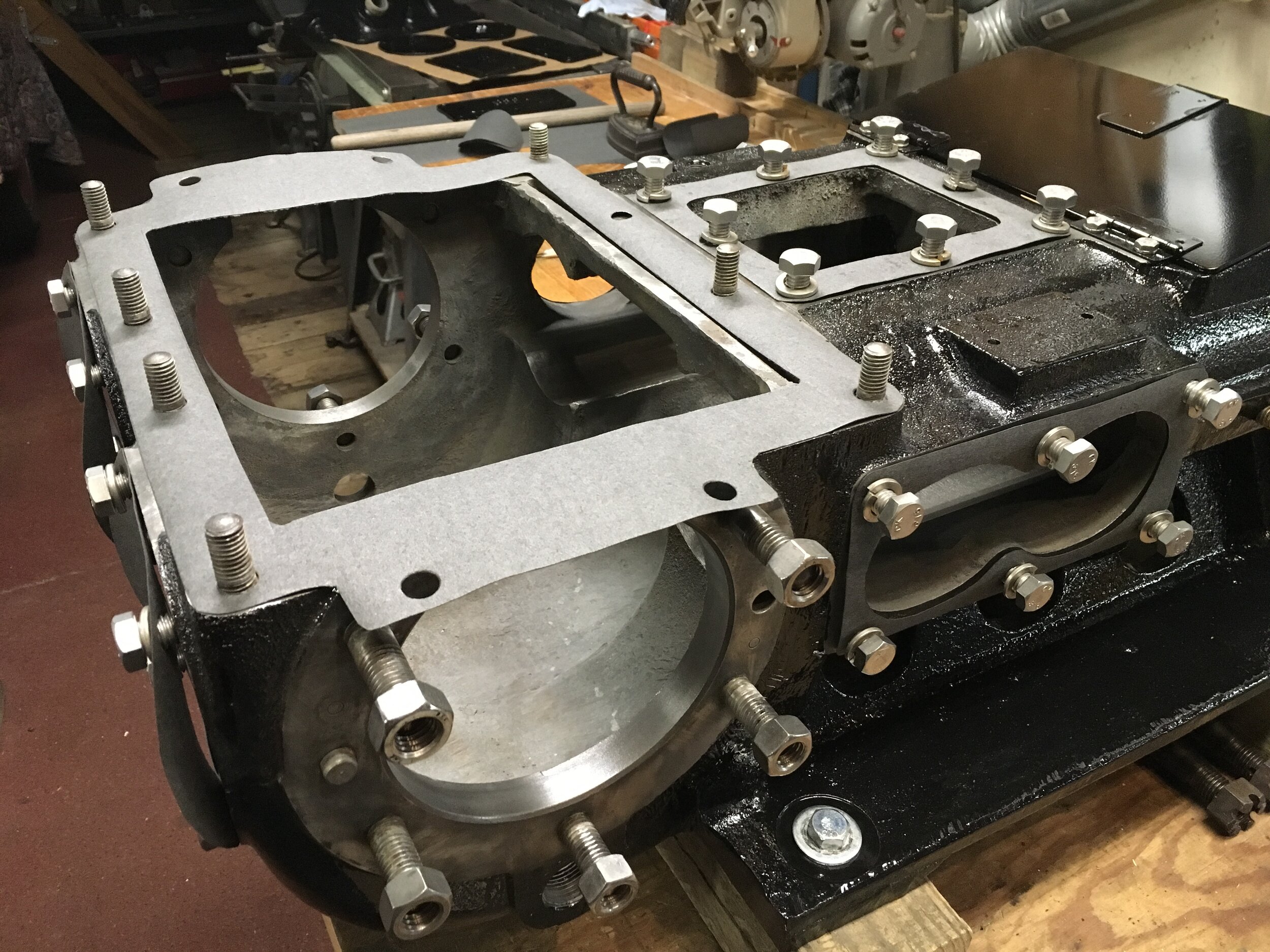

Bob also painted the cylinder block and made new fittings for the oil fill with the new oil breather installed.

The engine plate was riveted originally. Bob had to remove it so it wasn't destroyed in the caustic tank that cleaned the block. He drilled and tapped holes for brass screws and remounted it.

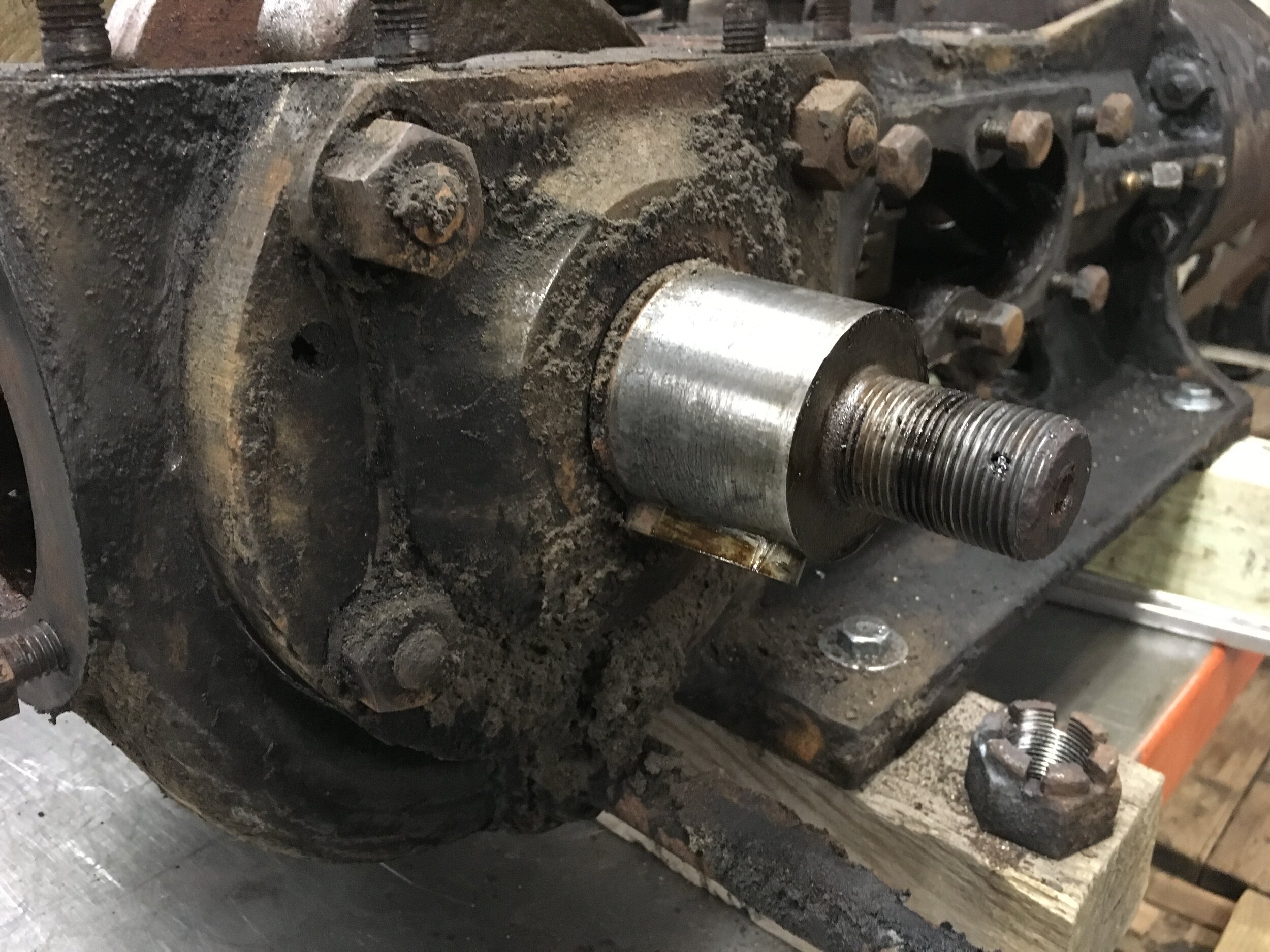

One of the piston packing gland nut lock screws was bent and broken. Bob made a replacement from brass. Images show the roughing out of the new one, then the single point thread turning. 1/2”-13 thread to a shoulder. Bob cut off the end that the tailstock center used and machined the tip that engages the gland nut. He machined the square head with a square collet holder block that allowed easy indexing to cut the faces. The last photo from left to right shows the unbroken original, broken original, and new replacement.

1/11/2020 Work Session

NESCo Signs Deal for Tender Body Replacement

1/4/2020 Work Session

12/21/2019 Work Session

12/14/2019 Work Session

Despite the heavy rain, we had an active crew on the job today. New volunteer Liam worked alongside Dave, needlescaling the right side drivers, and Alex gave everything a good coating of oil. Humidity in the building is picking at steel and iron surfaces. Roger Bennati, Alex Fogg, and Dick each worked on loosening the bolts which are keeping the left valve gear in place. Rog and Alex got six of the rather demanding nuts turning, while I did some cutting with a grinder. Leverett, Big Dave, and Dick each worked on loosening nuts on one tender pedestal, which my colleagues getting the most egregious one free after using a torch, hammer, and several wrenches. Bangor Daily News reporter Bill Trotter came out and did some interviews, took photos, and spent most of the day in our company.

12/8/2019 Work Session

Ron got the new compressor running and she's a champ.

Leverett did some work on the tender trucks but found a minor flaw (hairline crack) in the truck pedestal which will require remediation. Apparently the frame is steel and the pedestal is iron. Not a show stopper, but requires a different welding rod.

Roger and Dick needle scaled the third and second drivers on the engineer's side. Dick also cleaned up the frame a little bit. The frost on the drivers looks a bit like an octopus stretching out.

12/7/2019 Stoker Restoration Update

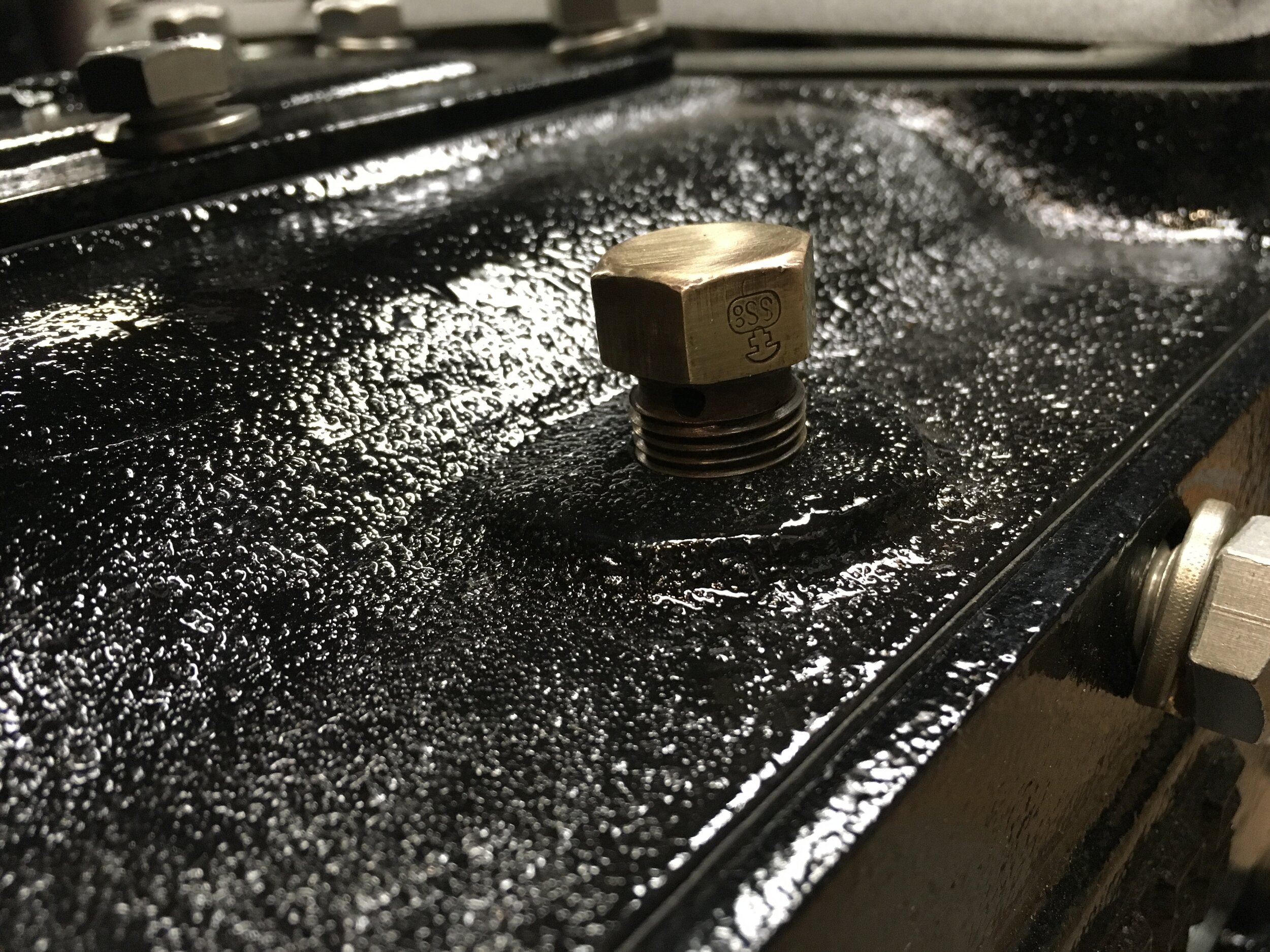

NESCo volunteer Bob DeWachter has been pretty busy at this! He powder coated the new oil breather, flywheel washer, steam port plug, and the locking fingers for the steam valve rod packing glands. He also refurbished the oil level try-cock. Pre-operational check, if oil comes out when open there is sufficient oil to run. And, he cleaned up the block vent. You can just make out the vent hole above the threads. Note the company logo and inspection stamp.

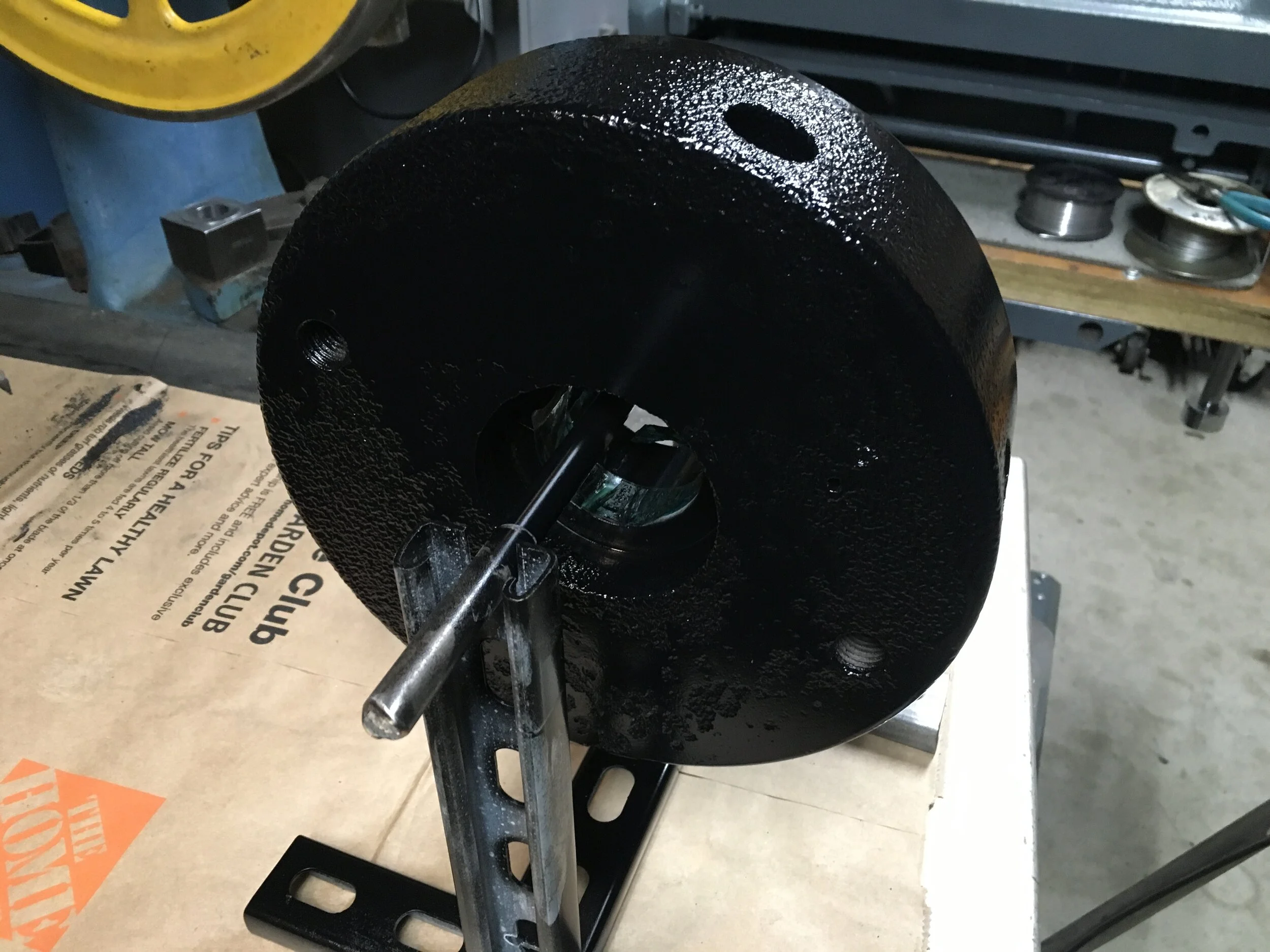

This is what the flywheel looked like upon removal. It took a bunch of time getting all the rust off and surface prep for powder coating. At nearly fifty pounds in weight, it took some doing to get it thru the process. The big break thru was making the stand to support the flywheel standing up. For the powder application, it just fit in the oven! About 2 hours of soak time to get to temperature, then 1/2 hour to bake. Then, nearly 4 hrs cooling down from 380 F. before Bob could handle it. There was quite heavy pitting on one side, but the back side was nice. Old grease/oil/dirt protected it.

Bob machined the two piston rods to remove the heavy rust pits. While conducting the machining setup, it became apparent that this had been done once during the engines service life, as 0.030” had previously been removed from the OD. Bob took another 0.032” to get to a 1.000” diameter.

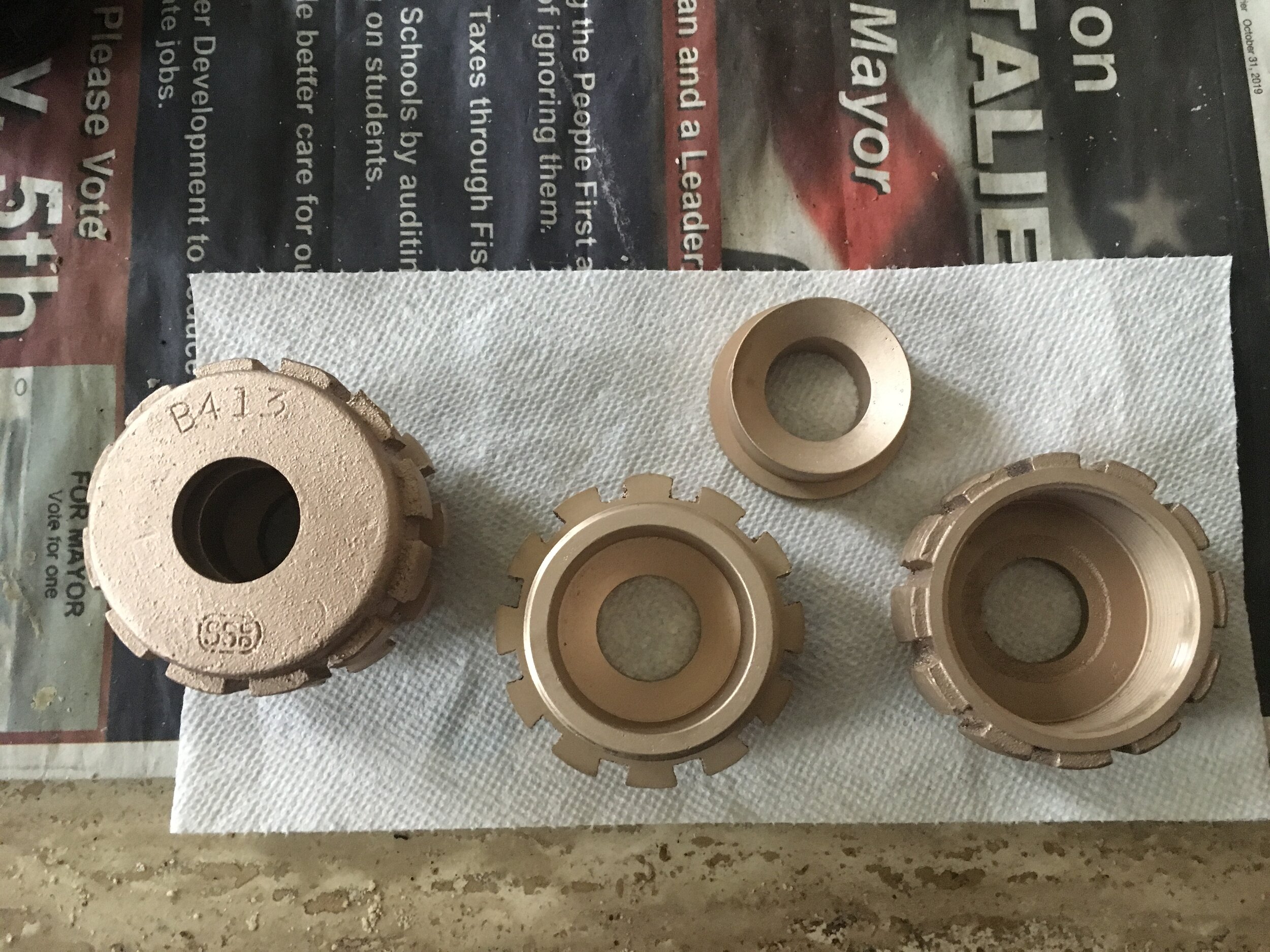

These are the piston rod packing assemblies. Bob used glass bead in his blast cabinet for these bronze parts. The soft packing has been removed. The internal bevels compress the soft packing to adjust tightness. The glands are turned with the red wrench it last weeks post. All four were cleaned up. The original packing is in great condition after all these years, but new packing will be fitted. The last photos show some test fit up. You can see the pair of brass gland lock screws on the left side.

11/29/2019 Stoker Restoration Update

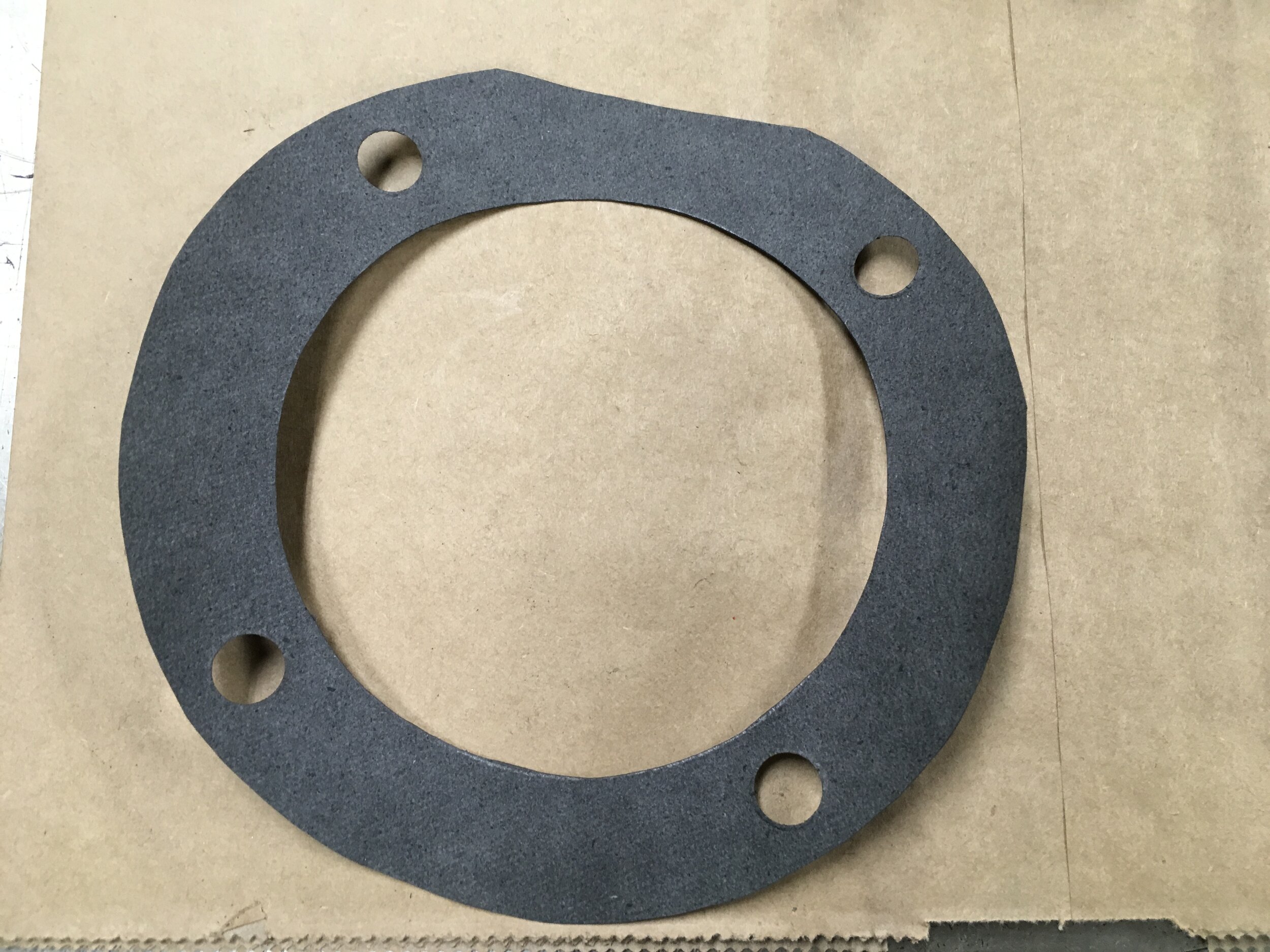

Unfortunately, the local Napa Auto Parts didn't have any steam engine gasket sets.......So Bob DeWachter made all the paper gaskets that were needed, using his press to punch clean holes right where they needed to be.

These images show one of the crankshaft main bearing caps at disassembly after a whole bunch of cleanup and prep.

These are the crankshaft main bearing caps being powder coated.

At one time, there was a breather cap for the crankcase oil fill pipe. All that was left was the mangled flange and threads. Bob rolled a case to fit the flange and formed a domed top, then welded it all together and blended the seams. This will eventually have a couple of Stainless Steel Choreboy pads inside of it to be the baffles. Then it will get powder coated.

11/19/2019 Stoker Restoration Update

NESCo volunteer Bob DeWachter has been hard at work on the restoration of 470’s stoker motor, and shared these photos this morning from his shop!

“I finally got the pistons separated from their rods. Had to use a friend’s large hydraulic press to pop them free from the tapers. The square block is a jig I had to make to properly support the back side of the piston body. Some parts have been prepped for powder coating. A lot of cleaning, wire brushing, and grit blasting to make them sanitary!”

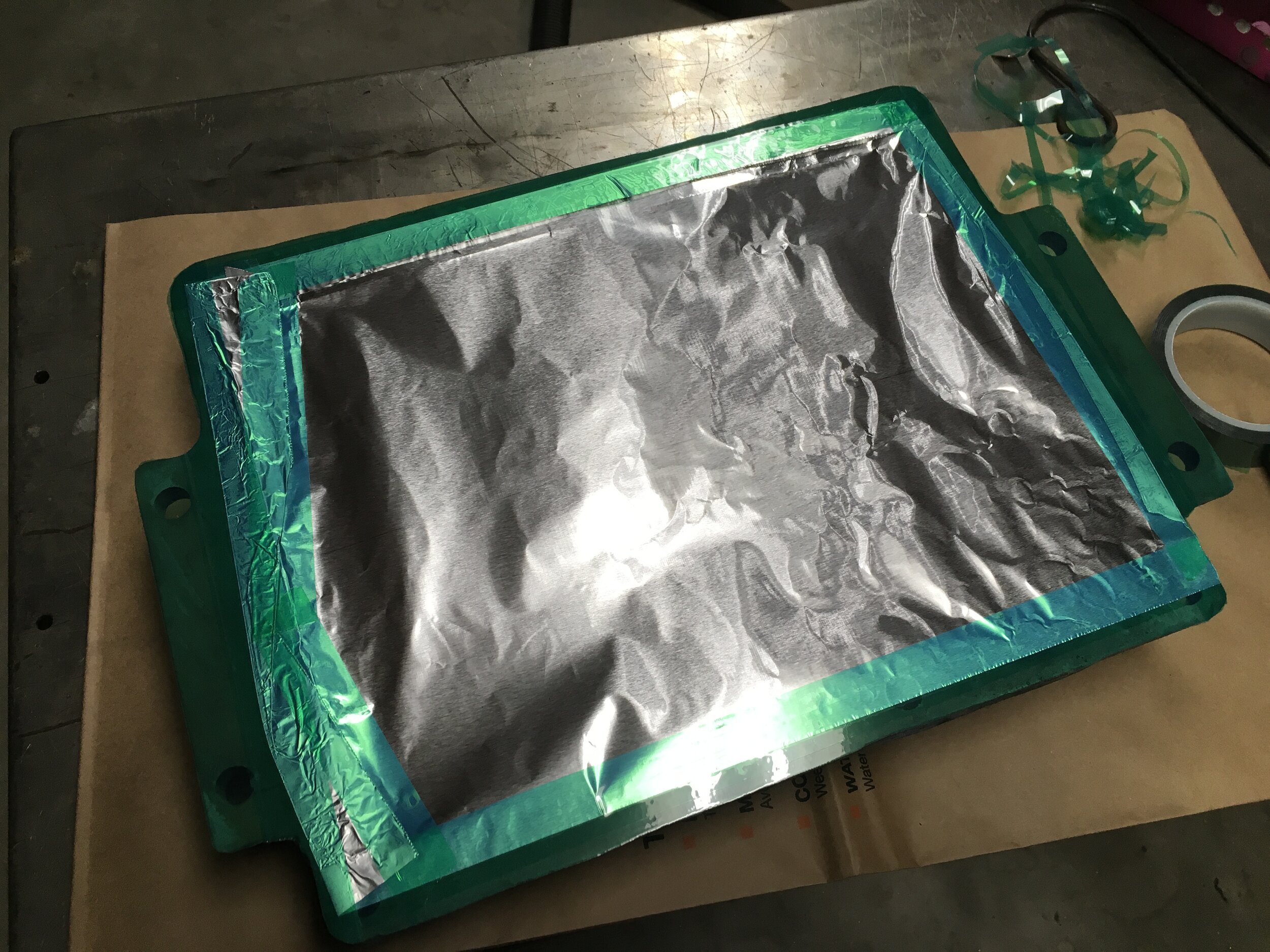

“Prepping and powder coating the upper block cover. High temp mylar tape and foil used to mask off interior and gasket surface of the cover.”

“This is the only original tool we have that saw service with 470. It is a spanner wrench used to adjust the packings on the stoker engine. Bright red so we don't misplace it! Held in place on the block by one of the packing locks. Upper block cover after unmasking. Upper cover set in place on the block.”

11/16/2019 Work Session

Hanna spent much of her time assisting Bob by cutting and grinding pipes, to be welded into a stand for repairing the 470 cab. Here you see grinding and welding!

Here are three images of the newly acquired equipment. The first shows the DESR compressor and the NESCO compressor new to it. Double-headed compressors would be a first, I'm certain. In the distance you see Al Jenkins, a man outstanding in his field.

The deck crane was fired up and tested out. There's a lot of ice to be melted, but it appears to function well. The blue boxes and rail wheels are a bonus that happened to come with the deck crane, allowing it to operate as a hi-rail vehicle, should the need arise.

The finished tender truck wheels were measured so the journal brasses can be finished to make a close fit. You can see where Dick and Roger ground out some old braze applied by the MEC shops, some 70 years ago to fill in wear on the tender truck pedestals. This area will be filled with steel weld and ground flush by Leverett. Also, the brake beams are undergoing repair at Leverett's shop.