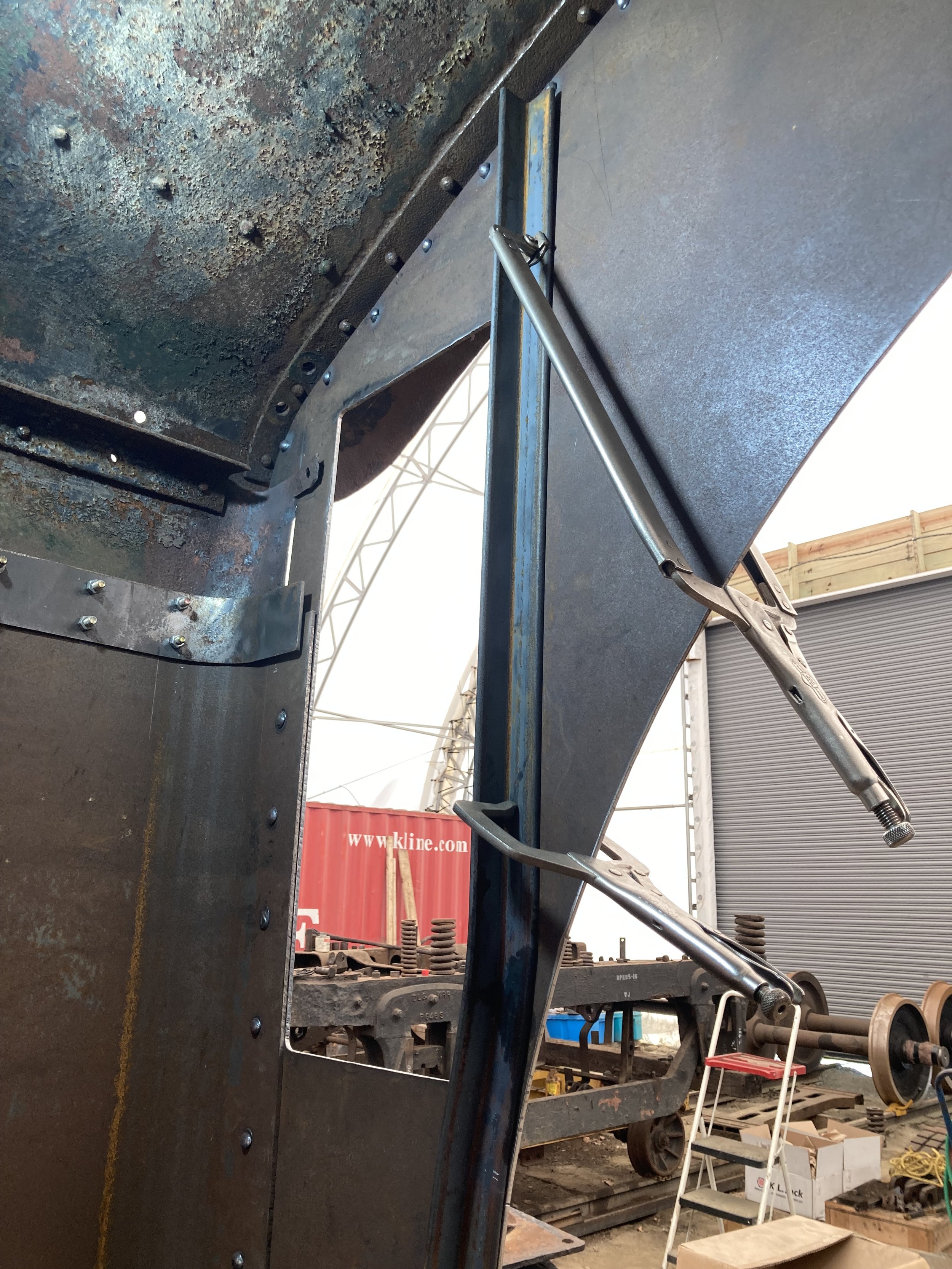

It was another fine early summer day in Hancock at the NESCo steam shop. Paul and Bob tackled fabricating the front wall internal bracing angle irons. These run from the roof to the floor. Starting vertical alongside the window framing, they kick out and then follow the profile of the boiler. Two mirror image struts were needed. It took some finesse to do the bending and capturing the curves needed. A couple of fixtures were made to assist in bending the angle iron and maintaining the 90 degree profile of the steel. One set up was Arm Strong operation utilizing a bit of heat and the other fixture was used on the hydraulic press. Which one used depends on whether you are stretching or compressing the web of the angle. We had one four foot piece of steel to practice technique on. After managing to torture and contort our practice piece into a pretty mangled piece of metal, it was off to the good stuff!! You have to be patient when doing this work. You start with a bit of eyeballing and chalk marks. Then, tweak it, refit, re-mark and bend it some more. Always keep an eye out so you do not go too far and keep the one face plumb that contacts the wall. In the end, they both came out very well. Next will be to lay out and drill the rivet holes that affix the struts to the wall. The new braces are a bit more elegant than what the Railroad had added over several front wall modifications and repairs. Unfortunately, there were not enough hands to go around to capture video or many pictures. There will be follow-ups on this in the near future.

We had three guests for a shop tour. Feel free to pay us a visit!