This is a detailed list of work accomplished to date regarding the rebuilding of the tender:

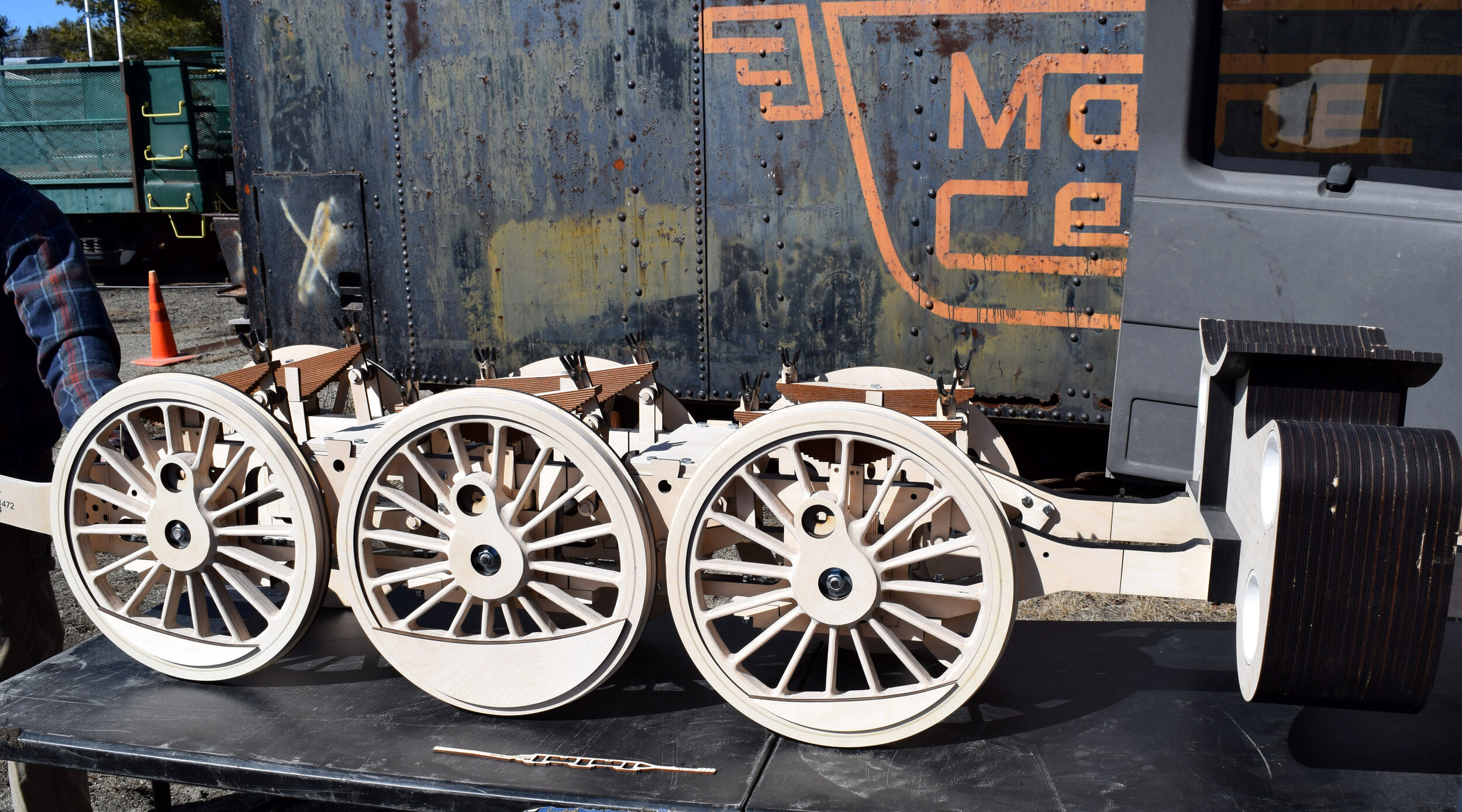

Number 2 tender truck was disassembled, parts cleaned and evaluated. Both brake beams were in poor condition, requiring them to be disassembled, repaired and reassembled. All new brake pins and swing hangar pins were made. All new bolster shims were made. One pedestal jaw was found to be worn excessively, so it was removed, repaired and reinstalled. The leaf spring assemblies were in poor shape, so all new ones were purchased for both trucks. The wheelsets were taken to Pan Am's shop in Waterville for machining of the bearing journals. One of the tie bars for the pedestals was found to be bent, so it was taken to Clarks Machine in Clinton to be straightened. The truck was reassembled last summer and is ready for service.

Last year we took delivery of the new tender tank built for us by Millinocket Welding and fabrication. Once the number 2 tender truck was completed, the tank was loaded onto 2 pushcars and rolled inside the shop. Since then, most of the vertical holes have been drilled for rivets. The ladder inside the tank has been reinstalled.

The number 1 tender truck has been disassembled and parts cleaned. Because this truck was under the coal bunker, it was in worse condition. The old bolster shims were badly rusted and required a Sawzall to cut through them in order to free the bolster. The wheelsets needed both the bearing journals and treads to be machined. The inner coil springs were in poor condition and new ones were purchased. There were 4 excessively worn pedestal jaws on the truck frame that required repair. The brake beams while not worn excessively, will need some work done to them and one is badly rusted and is now being welded to build up areas of wasteage. Both tie bars were bent, not as bad as the other one, but enough to require them to be straightened. The safety bars that go under the spring plank were badly rusted will be replaced with new ones. We have them, but a special tool needs to be made to countersink the drilled holes so the flathead screws can be used. So far, the pedestal jaws have all been repaired, the tie bars have been straightened and the brake beams are being repaired.

The tender frame has gotten sandblasted, painted and new wood slats made. The drawbar pin holes have been line bored and new sleeves and pin are being made. A new brake pipe has been made and installed.

The following work remains to be done in order to complete the tender:

Reassemble number 1 truck. The brake beams need to be finished and hung in place before it can be re-wheeled. New journal box seals need to be put in (we have them). The journal boxes and equalizer bars need to be put together, then the frame can be picked and lowered into place. The safety bars, swing hangars and spring plank can be put in. This truck had shims between the swing hanger and spring plank, so new ones will need to be made prior to assembly. Once the spring plank is in, the new leaf springs can be put in, then the bolster. All the shims, brake rigging can be put in, too. This truck should now be ready to put back in service.

At this point, the frame should be ready to put back on the trucks. This will require the big crane to make the pick. Both trucks will require accurate placement. Once the frame is back on the trucks, a number of measurements will be needed. The clearance between the bolster side bearings and the drawbar heights. The coupler and draft gear will need to be put back in to check this, but it will need to completely disassembled and inspected first. The heights will need to be set high, as everything will settle after the tank is mounted and when the tank is loaded. After this, the tank can be mounted to the frame. After it is set, accurate placement is critical so the mounting lugs can be located for riveting. Also, the water outlets will need to be marked and cut out. This may require the tank to be removed again so this may be accomplished. Once this has been done, the tank may be permanently secured. The last major thing to be done is to begin riveting.